Not Just Three Numbers: Understanding fertilisers: What to use where, when and why

By Chris Humphrey MBPR FQA – Technical Manager, Collier Turf Care

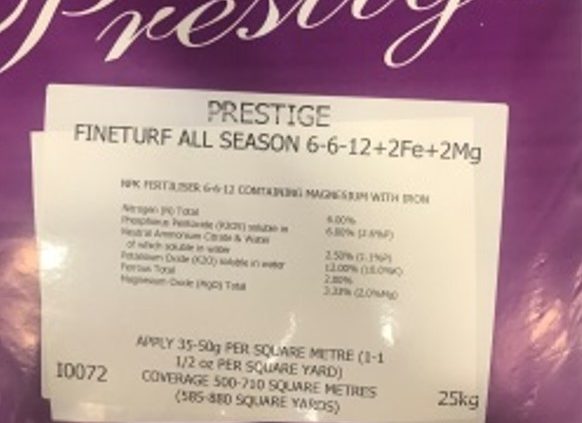

We are all familiar with turf fertilisers being referred to as three numbers (for example 6:6:12) but what does it really mean and what are we putting on our turf? To start, the three numbers are just what is required by legislation to be on the fertiliser. They relate to the percentage of major nutrients Nitrogen, Phosphorus and Potassium (NPK) in the product. But you need to know a lot more.

Read the label and discuss with your FQA (FACTS qualified advisor) your requirements. FACTS is the Fertiliser Advisor Certification and Training Scheme. Is your advisor qualified?

Ask to see their FQA card.

Why do we apply fertiliser?

Turf needs many nutrients to remain healthy and it is important to ensure that they are present in the soil in sufficient quantities and are available to be taken up by the plant.

Typical level of nutrient in grass.

Major nutrients

Nitrogen – 2.50 – 6.0%

Phosphorus -0.25 – 0.50%

Potassium -1.25 – 3.50%

Secondary nutrients

Calcium -0.40 – 0.70%

Magnesium -0.05 -0.25%

Sulphur -0.25 – 0.50%

Micronutrients

Iron -60 – 400ppm

Manganese -50 – 400ppm

Copper -50 – 400ppm

Zinc – 2 – 30ppm

Boron – 2 – 5ppm

Molybdenum – 2 – 5ppm

Nutrients are lost through leaching through the soil and clipping removal. But how much should we put on and in what form? Nutrients come in different forms and vary in speed of delivery, potential to scorch the turf, the effect on soil pH, availability at different temperatures, granulation size, longevity of response and physical breakdown. Nutrients also come from different sources. The major nutrient – Nitrogen – can come as Ammonium Nitrate, Sulphate of ammonia, urea, an organic source or as a synthetic nitrogen.

Ammonium Nitrate and Sulphate of Ammonia will release quickly and give a fast response at low temperatures, they will therefore not last as long as other nitrogen forms and do have a higher scorch risk. Sulphate of ammonia is also quite acidic which could be a useful or not depending on your soil pH and requirements. Urea needs bacteria to convert it to nitrate for the plant to take it up, therefore it needs some moisture and the temperature to be above 6 degrees centigrade to get it working. Organic nitrogen comes in any format where organic matter can breakdown with bacterial activity to release nitrogen. The common ones used in turf fertilisers are Bone Meal, Dried Blood, Poultry manure or Leather-meal. By the fact that organic nitrogen scores need to be broken down, they are a fairly slow release of nutria and do require some moisture and temperature to help them. The exception is Dried Blood that does break down quicker than the other organic forms. Because Organic fertilisers are slow they have a very low scorch potential. Most fertilisers that call themselves organic are actually only organic based and have a degree of inorganic nitrogen in them. Check the label or ask your FQA. The final source of nitrogen is the synthetic nitrogens such as Methylene urea, IBDU, Resin coated urea or Sulphur & Resin coated urea. These are designed to give you a slow release over a set period, often up to 9 months. They generally therefore have a lower scorch potential. It is important when using any coated product that the granulation is a suitable size for the turf area where you plan to use it and maintenance operations do not break the coatings.

How much nitrogen should you put on? This will vary on many things such as soil type, leaching potential, grass type and growth rate. You should prepare an annual fertiliser programme based on your individual requirements and the results of a soil test.

To work out how much nitrogen you are applying use the following formulas to give you the Kg/Ha you will be applying.

For Granular products

(Application rate x % Nutrient) divided by 10

Example – Apply a 4:0:8 fertiliser at 35g/m2

(35 x 4) divided by 10 = 14kg/Ha of nitrogen.

For Liquid fertilisers

(Application rate x specific gravity x % Nutrient) divided by 100

(specific gravity is the weight of a known volume of liquid fertiliser vs the same volume of water)

Example – apply a 15:0:12 liquid fertiliser at 60ltr/Ha. The liquid fertiliser has a specific gravity of 1.2 (i.e. it is 1.2 times heavier than water).

(60 x 1.2 x 15) divided by 100 +10.8kg/Ha of nitrogen.

Every site will vary and many things need to be taken into consideration when planning your fertiliser programme but as a rough outline of common nitrogen inputs are:

| Golf Green/Bowls/Ornamental Lawns |

80 – 120kg/Ha |

| Soil based Golf Tees |

80 – 160kg/Ha |

| Sand based Golf Tees |

200 – 240kg/Ha |

| Cricket Square |

80 – 120kg/Ha |

| Soil based Football |

80 – 120kg/Ha |

| Sand based Football |

200 – 800kg/Ha or even more. |

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.