What is it about Durham?:Scott MacCallum talks cricket with Durham School’s Head of Grounds Barry Boustead, learns how a merger with the city’s Chorister School has brought together 600 years of heritage, and muses about THAT song…

One of renowned singer song-writer (and whistler) Roger Whittaker’s most famous pieces of work was Durham Town, in which he sang “I’m going to leave old Durham town.” It’s a lovely song, but having been to Durham recently, I can’t see any reason why anyone would wish to leave.

What is it about Durham?

There can be few more beautiful places in the country in which to earn a crust than Durham – named a UNESCO World Heritage Site in 1986. The sheer beauty of the famous cathedral, which sits majestically above the historic buildings, give it a mystic which would be hard to replicate anywhere. Oh, and it’s a City despite what Roger says. Probably “city” didn’t scan as well as “town”!

One man who has no intention of leaving Durham any time soon is Barry Boustead, Head of Grounds at Durham School, for whom gazing over his view after a full day’s graft is very much balm for the soul.

“My place of work really is quite spectacular. There are not many better settings than this,” said Barry.

“Like many jobs you can occasionally get a bit fed up, but then I just look out over our main rugby pitch to the cathedral and everything seems a little bit better.”

But the fact that Barry has been at the school for 13 years suggests that those days when a “fix” of the view is very much required are few and far between.

“It is a good place to work. I wouldn’t have stayed so long otherwise,” he said, before admitting that his original Plan A had been to remain for around four years and then emigrate to New Zealand!

The job Barry started out with has changed since he began as Head of Grounds, however. He has added the Gardens portfolio too, while a merger with The Chorister School in the city, just last September, bringing together a shared heritage of over 600 years, has increased the number of children using his beautifully prepared pitches and grounds, while adding to the complexity of his role.

“We have inherited two playing fields, one of which has three junior rugby pitches, while I don’t know what the plans are for the other as yet. Personally, I’d like to be a training area to keep them off my rugby pitch, but it will bedown to the sports department at the end of the day,” he laughed.

As part of the merger Barry has acquired one new part-time member of staff, Jon Bland, who had been working at The Chorister School, but with Barry himself and two other staff, Damian Merrigan and Darren Keeler, they are certainly kept extremely busy.

“Even visiting the new fields can be a challenge as they are on a busy road and at peak times, or as was recently the case, when a bridge was closed and traffic diverted, it can take 10 to 15 minutes just to make the right turn before we can get back. That sort of time can add up and over a week can be quite significant.”

What is it about Durham?

And time is one thing the team can’t really afford to lose. Particularly over the autumn period when, on a site with so many mature trees, clearing leaves is the Durham School equivalent of painting the Forth Rail Bridge.

“It’s a daily job from October through to January and we clear every leaf off the site pretty much.

We collect them and put them in a pile behind our shed which just builds up and then rots down.”

How many man hours a week are devoted to the task?

“This week for example two of us have been on the job and all we have done is leaves so it’s anywhere upwards of 50 hours a week. Other jobs do take priority but so much time is devoted to leaf clearance. I always have a target of getting every leaf cleared by Christmas, but I’ve not done it yet!”

The other on-going issue, also tree related, is the school’s artificial hockey pitch, which sits in a lovely, secluded site surrounded by trees.

“Being surround by trees means that silt – dust or sap – has collected within the profile. Then when we get a heavy downpour the silt rises to the top and it gets very slippy – not something you would want on an artificial pitch.

“We’ve tried different brushing machines and it has improved slightly but we are going to see how this winter goes before we see what our next step is. We are using a SISIS Twinplay with stiff brushes and it seems to do a good job. Ideally, we’d like to do it twice a week but pressure of work means that we can only fit it in once a week. It’s an on-going problem.

“One solution would be to take out the existing sand and replace it but that is costly.”

With leaves taking up a significant part of the year it is grass cutting which occupies the rest and with cricket, in particular, it is an intense fixture list.

“We can have three or four fixtures a week and we have 12 match strips on our main cricket ground and three down on the bottom ground,” explained Barry, adding that the main cricket pitch shares its space with the first team rugby pitch – which boasts sets of posts which reach a remarkable 17 metres – the same height as those found at top grounds such as Twickenham.

To prepare the cricket wickets Barry and the team rely on a single Allett C20 wicket mower, which makes advanced planning an essential part of the job and leans heavily on the reliability of the mower.

“I get the fixtures in at the beginning of the season and then fit in the Cup fixtures as the teams progress through the tournament. I do have a good relationship with the Director of Cricket so he has a good idea of what we are capable of producing.

We can hold three fixtures at once – two on our upper field and one down in the other field.”

On the reliability? Well, that’s not always down to the machine itself.

“I did clip a stud and bent the bottom blade on our Allett,” confessed Barry.

“Fortunately, we do have a good relationship with the University. I started my career there and was at school with the Head Man, Paul Derek’s, kids, and we do help each other out. They helped me with a wicket mower after the bent bottom blade incident, and last summer they had a problem with their tractor, which they use to cut their big fields with gang mowers, so they were able to use our Kioti.”

That kind of mutual back scratching can help solve immediate problems, but also ease the budgetary strain on hire fees which can, with the now longer lead times on spare parts, mount up quickly.

If pushed, Barry would say that his first love is cricket and his aim is always to produce the best surface possible.

“I’m a big believer that a good cricketer will be able to react to any situation and while I do talk with the Director of Cricket I’m never under pressure to produce a wicket to suit our own team. What they see is what they get,” said Barry, who while he didn’t ever play the game, has a real passion for preparing cricket wickets.

So much so, in fact, that he spent a week with Vic Demain and his team at Chester-le-Street working at a Durham county match.

What is it about Durham?

“The week I had was really good. I learned so much, mainly from seeing how the team all operate and come together to work towards the same goal. Vic and I are still in touch and he helps run the Durham Groundsman Association. He is a great communicator and having come from grass roots level has a real affinity with guys in our position – those working with one wicket mower!”

Barry’s arrival in the industry came about very much by chance. He’d begun a degree course in business management at Sunderland which involved a placement working for a year at a local council.

“It was working in the marketing department, but I soon learned that being stuck behind a computer just wasn’t for me. I left and found a position on a summer contract working on the grounds’ team at Durham University.

“When a full time contract came up I got the job and loved it.

They put me through my NVQs at Haughall College, which was just across the road. I did my NVQ 2 in sports turf and my NVQ 3 in sports turf management. I knew at that stage that it was the career for me,” said Barry, whose previous experience had amounted to cutting his dad’s lawn on a weekly basis!

After four and a half years the Durham School position came up and Barry got the job.

As he looks out at the fabulous view of the Cathedral, he has never had any doubts that he chose the right career and is very happy at Durham. Roger Whittaker on the other hand…

EQUIPMENT INVENTORY

JCB 354 tractor

JCB Workmax

Major tractor mounted

roller mower

Toro 6500d

Kioti WD 1260 ride

on mower

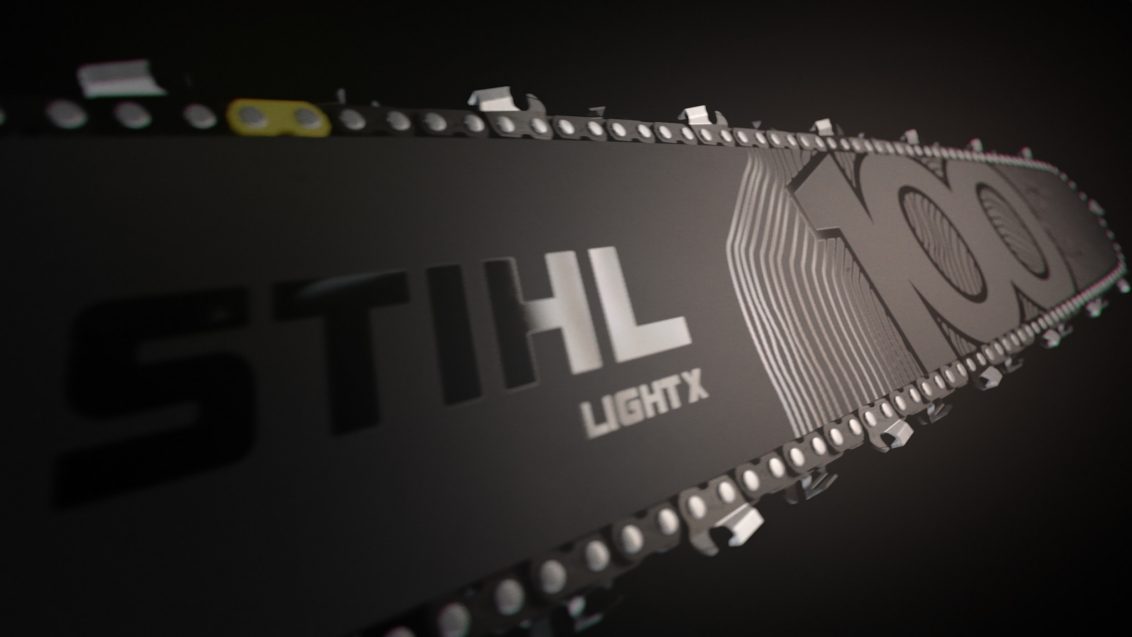

3 x STIHL battery

pack blowers

STIHLl BR 600 petrol blower

Billy Goat blower

2 x STIHL strimmers

2x Honda rotary mowers

Ferris FW25 mower

SISIS Twin play

SISIS Rotorake

Allett c20

Dennis 36inch cylinder mower

And my most important and favourite tool in the shed, says Barry, the SISIS Combi Rake.