Ransomes to Showcase New TR320 and HM600 at NEC

Ransomes to Showcase New TR320 and HM600 at NEC: Ransomes, the Ipswich-based manufacturer of commercial mowing equipment, will be showcasing the brand new TR320 triplex cylinder mower. Ransomes will be exhibiting on stand H090 at SALTEX in November.

The Ransomes TR320 is one of the lightest machines on the market, ensuring that surfaces are kept pristine. A combination of narrow transport width (1.64m (64.5”)), a 1.83m (72”) width of cut, superior slope capabilities and manoeuvrability, allows operators to safely negotiate the tightest of spaces and most challenging terrain. Designed and manufactured at Ransomes Jacobsen’s European headquarters in Ipswich, the TR320 is primarily targeted at the sportsturf and landscaping market, providing a quality maintenance solution for sports pitches, estates, and light municipal applications. You are invited to come along to stand H090 to see the latest innovation from Ransomes.

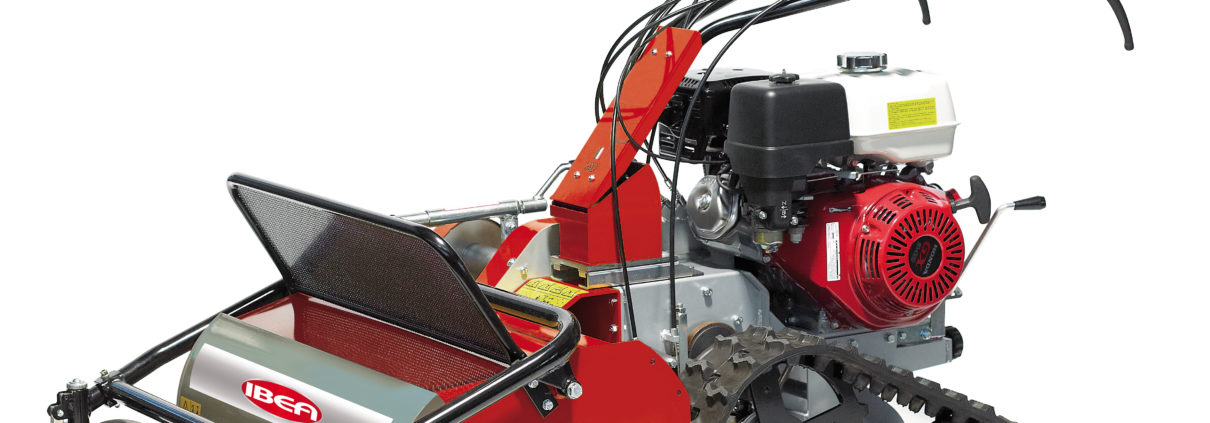

Also, debuting at SALTEX 2017 is the HM600. Built on the foundations of the Ransomes MP wide area mower platform, the HM600 builds upon this, providing users with the ability to run three heavy duty flail mowers with mulching technology from Müthing. With all mowers engaged, the 3.2m width of cut delivers exceptional productivity. The fingertip control of individual units makes trimming around obstacles easy and brings new levels of versatility to flail mowing. Units fold up securely to transport easily between work areas and access confined sites.

Ransomes is proud to be sponsoring the SALTEX College Cup for the second time; introduced by the IOG as a brand-new national student-led sports-turf challenge that will take place on the first day of SALTEX 2017. It is an academic test of turf management knowledge for student competitors in teams of four who are enrolled at colleges throughout the UK on relevant courses of study.

As one of the groundcare industry’s major manufacturing companies, Ransomes will also be showcasing other municipal mowers plus Cushman utility vehicles, Iseki tractors and turf maintenance equipment from the Turfco and Ryan brands.

For more information, visit: www.jacobsen.com/europe

For the latest industry news visit turfnews.co.uk

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.