Trimax From The Start: Trimax founder and Managing Director Bob Sievwright talks to us about how far he’s brought the company from its origins in the 1980s, flail mowing the grass under kiwifruit vines in the Bay of Plenty.

Now with offices in the UK, US, Australia and New Zealand as well as distributors across Europe, Trimax has built an unparalleled reputation among turf maintenance professionals for cut quality and machine durability.

Trimax From The Start

The Tractor Whisperer

“I’m a farmer’s son,” says Sievwright. “I grew up on a small back country cattle and sheep farm where the main challenge was converting rough scrubland into decent pasture for the animals. My siblings, my twin brother and I worked every hour available after school, weekends and holidays. Most of the pulling on the steep hills was done using horses, but it turned out I was useless on a horse; I kept falling off. So, from the age of about 12, I gravitated towards the tractor and farm machinery. The horses knew they were smarter than me but the tractor always did what I wanted!”

Always looking for a better way

That strong work ethic and an affinity with machinery were two things that would prove critical in Sievwright’s career, as well as the sudden death of his father in his last year of high school. “I realised at that point it was up to me to get going and see what I could do. I got myself an overseas scholarship as an Engineering Cadet with General Motors New Zealand and later in Flint MI, which is where I did my Engineering degree, and learned all about car manufacturing. I came back in 1974 and got the chance to start my own company.” Not Trimax. It would be another eight years before Sievwright moved into the machinery of grass cutting. Before then he would hone his business, sales, marketing and export skills making meat hooks for local abattoirs from hardened and tempered spring steel.

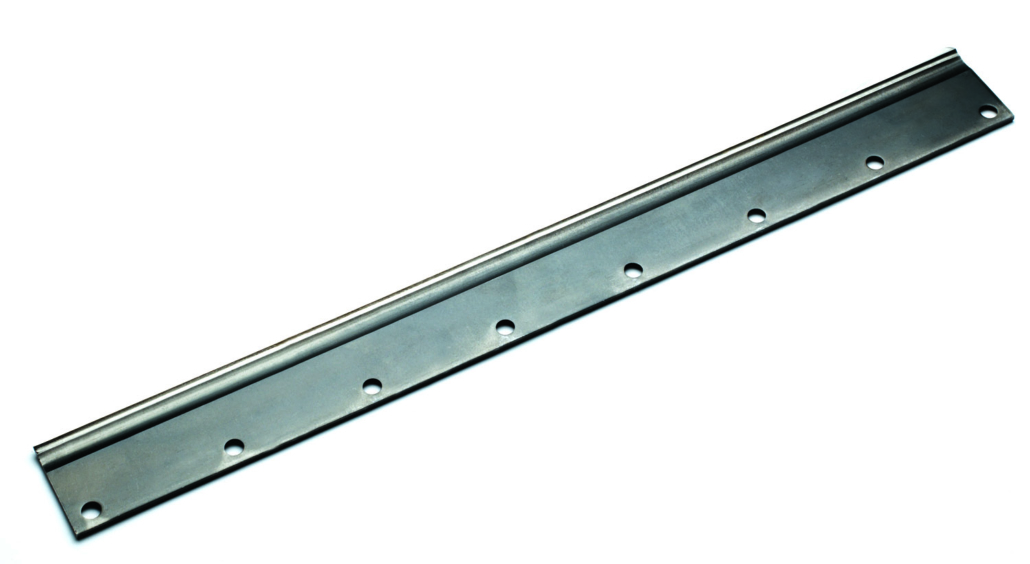

On one of his meat hook business trips in 1981, 33-year old Sievwright spotted a flail mower with a blade made from two steel pieces welded together. “I sat down and sketched a blade that I knew we could make from just one piece of steel and sent it to the manufacturer. He liked it and we got an order for a thousand blades: my first order for the Gamma flail!” That particular mower manufacturer bit the dust a couple of months later and Sievwright’s blade deal fell through, but he wasn’t fazed. He decided to up sticks, move his business and his young family to Tauranga, New Zealand to manufacture the mowers and the blades himself. He hired a mower engineer (Norm Miller, who still works at the company’s HQ today) and went into production. For Bob meat hooks were out and Trimax Mowing Systems was born.

Inspiring productivity

The first Trimax models on the market – Ezeemow, Mowcraft and Mulchmasta – were originally aimed at New Zealand’s booming kiwifruit farming industry. But demand soon grew from park groundsmen and reserve landscapers who had heard of the mowers’ reputation for durability, quality of cut and low maintenance. In 1985 Trimax diversified into rotary mowers and purchased a complimentary mower manufacturing business, owned by Jim McEwen. Sievwright says: “Jim had design skills that I can only describe as an art form. All his mowers looked great and mowed well, so I invited him on board; we worked well as a team and together we had easily the lion’s share of the local municipal market in New Zealand.”

Jim McEwen set up Trimax’s first Research & Development department. He explains the company’s success. “We have always challenged the status quo and offered a fresh approach to mower concept and design. We produce machines that are aesthetically pleasing, exceed the customers’ performance expectations and have a longer life.”

We see possibility

In 1985, Trimax started exporting their pioneering mowers, the Procut and the Stealth to Australia. All part of Sievwright’s vision: “I was determined we would export as I’ve spent almost half my life outside of NZ. Part of the design parameter was always that our mowers had to be internationally saleable, commercial quality products that delivered long-term value. Trimax has succeeded where others failed by offering premium products, premium service and always listening carefully to the end-customer. Jim and I have travelled overseas many times, trying to understand what users need in each market.” After rotary mower Stealth S1 set a new standard of grass cutting in Australia, it came as no surprise when Trimax started exporting to the UK. Brits loved the Stealth S1 too and by the end of the 1990s Trimax had opened their first UK office and warehouse in Northamptonshire. Trimax mowers were now being used in many prestigious locations including Windsor Castle and the ten perfect polo pitches at the nearby 130-acre Guards Polo Club.

But not content with cutting the Queen of England’s lawns, Sievwright set his laser-sharp sights next on the USA. Trimax sold its first rotary roller mower there in 2001 and opened up a distribution warehouse in Georgia in 2005. Tinkering away with America’s grand scale in mind, the research and development team launched the X-WAM in 2009, a 10m-wide monster, like nothing else on the market. The scale, reliability and pristine cut of the X-WAM meets the needs and boosts the profits of the country’s mammoth turf farms. Just Google Trimax X-WAM and wonder at the size of it.

Marketing-led approach

Trimax had hired its first marketing executive in 2001. Before then the business attributed its two decades of growth to great salesmen. “We won a lot of customers throughout the 80s and 90s by demonstrating our products” recalls Sievwright. “When I started there were seven other mower manufacturers in NZ. We had to be different and we had to prove we were better. When you’re so sure you can outperform your competitors, you have no hesitation doing side-by-side battles. We won them all.” Sievwright’s proud of his products’ ability to perform but acknowledges that today’s business environment demands a more marketing-led approach: “We still need to demonstrate as much as possible but we do that while also sharing the Trimax story.”

Innovating with purpose

“Our approach to innovation has always been driven by customers. We listen to how they use their products and design purposeful innovations to help customers achieve their potential”. It was this approach which led to the development of one of the company’s most iconic mowers – the Snake! A fully dedicated sports turf mower, utilising 30 years of innovations and refined engineering practices all rolled into one incredible product. Released in 2014, “the Snake solved many challenges and transformed the lives of many groundsmen across the globe”.

“As a kid I always remembered our farm equipment needing lots of tedious maintenance and how frustrating and costly break downs would be”. His ability to relate and empathise with customers, coupled with his desire to push new boundaries, Sievwright says “the ultimate goal would be to produce a zero-maintenance mower”. With that in mind, Trimax went on to develop an array of innovations, such as; SteadFAST maintenance free spindles, auto-belt tensioners and the LocTEK stubless roller retention system, all focused on bringing Trimax one step closer to the ultimate goal.

Trimax From The Start

Powering performance

With sales continuing to boom, in 2015 Trimax expanded their UK operation by purchasing a 16,279 sqft facility in Northamptonshire, and in 2019, a 25,000 sqft facility in Georgia, USA. With offices now around the world, employment numbers soring to 100, and an ever-expanding community of Trimax users – this was something Sievwright only dreamt of!

With Trimax still only scratching the surface of what the huge USA had to offer, Sievwright rooted himself in the market and made it his mission to better understand their needs. “Each market that we operate in is truly unique, as are the requirements of each individual. It’s important for us to acknowledge this so that when we are developing mowers, we can be sure they meet these requirements without compromise”. Needless to say, it wasn’t long before Sievwright identified an opportunity – an opportunity to build a new concept of a castor wheeled mower!

Not afraid to follow what the market required, Trimax and the team set about developing their first ever castor wheeled mower, later named – The Vulcan! Having only just been released in the USA market in 2019, this 7m wide mower is sure to impress!

Personal partnerships

Despite taking a step to the side and passing the reins over to the next generation (his son Michael), he still remains a very active salesman (as he describes himself) within the business. “I’m so proud when I see how much the whole Trimax team continue to fight for the customer. It’s what got Trimax this far, and it’s what will ensure we have a long and creative future”

What started out as a family-run business whose innovation was founded on culture and driven by community, is still very much that. A culture of partnerships which challenge the status quo, inspire productivity, and raise the bar on results.

Trimax is proof of what can be achieved when the right mix of culture, partnerships and innovations are put together! It’s only a matter of time before we see the next Trimax mowing innovation enter the market!!

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.