Making a mark: Scott MacCallum meets Andy Butler, the Head of Grounds and Gardens at Repton School, a man who is fast making his mark…

For 14 years Andy Butler diligently worked his way through the ranks of the grounds team at Repton School. He studied hard to gain qualifications, but, like so many who have gone before him, when he reached the level of Deputy his progress stalled. The Head of Grounds and Gardens role was already filled and family commitments meant that moving any distance away to another school wasn’t a real option.

Making a mark

Then, just over a year ago, came a breakthrough. The head man moved on to another school and the job that Andy had always coveted became available.

Knowing that this was his big chance, he prepared thoroughly and when it came to his turn to face the interview panel, he aced it.

“At the interview I just wanted to be treated like any other candidate and thankfully that was the case,” he said.

“I presented them with a plan covering where I wanted to take the school over a five and a seven year period and we are now implementing that plan,” he explained.

“I split the school into three areas and planned to do a rolling programme on each, every three years. So now every area will be getting regular vertidraining, regular overseeding, regular top dressing.

“We are trying to change the soil profile as it is quite clay-based where we are so we are inputting lots of straight sand to improve that profile and the water flow through it,” said Andy, who uses Mansfield Sands, based nearby.

In the nine months since he took over, the school has been delighted with what Andy and his team have already put in place.

“We have implemented a rigid aeration programme. In fact, the guys are out there just now working on it, with the Air2G2, trying to relieve compaction and improve our root growth. The improvement in the first eight months has been pretty good,” said Andy, adding that previously there hadn’t been a particular focus on that type of remedial work.

But they have not just upped the aeration work. A new drainage project is proving to be a little more complicated than was first envisaged.

“We drained one pitch, but unfortunately, due to the fact that no compaction work had been carried out in the recent past, and with heavy tractors pulling gang mowers increasing compaction issues, the water wasn’t able to find its way to the drains.

Making a mark

“I think we are going to have to use the original drainage as secondary drainage and put a primary drainage scheme in on top of that. We will then roll that method out over the other three areas we have on the site.”

The work will undoubtedly improve the facilities at what is one of the very top schools, not just in Derbyshire, but the entire country. Indeed, the roll call of Old Reptonians, sporting and otherwise, would equal those of any similar establishment.

I give you Harold Abrahams, winner of the 100 metres at the Paris Olympics in 1924, and immortalised in the Oscar-winning film, Chariots of Fire; Bunny Austin, Wimbledon finalist in 1932; Adrian Newey, the Formula 1 technical genius, and a host of cricketers, including Donald Carr, who went onto run English cricket.

There is one other sporting Old Boy who needs a special mention, and that is the legendary C B Fry, who not only played cricket and football for England, and represented the Barbarians at rugby, he equalled the world long jump record at the time, and he could back flip from a standing start onto a mantlepiece!

A skill perhaps perfected in one of the Repton Houses.

If that were not enough, the education of the man who gave us Charlie and the Chocolate Factory and Tales of the Unexpected was shaped at Repton – Roald Dahl.

Another pupil to go on to national fame was Jeremy Clarkson.

It is doubtful whether many of those illustrious sportsmen had the range and quality of sports surfaces that are now a feature of Repton School.

The school currently has: two water-based Astro pitches; one sand-dressed Astro pitch; the Prep school has another sand-dressed pitch which is being replaced later this year; there are 12 tennis hard courts, which switch around to host the netball season; 11 football pitches; two rugby pitches; one 11 pitch cricket square; two six pitch cricket squares; the Prep school has one six pitch cricket square and two other cut down pitches for the smaller children.

“We have roughly 27 acres of playing field at the Senior school and 20 acres of playing field at the Prep school while we also have 10 boarding houses at the Senior school all with gardens and two boarding houses at the Prep school each with a garden.”

Often pitches are shared by rugby and football and it can be a challenge to turn them around between sports, while the First team football pitch also doubles up as the cricket outfield with a four week turnaround to make it happen.

“We overseed and level up as best we can.”

Andy has a school calendar at the beginning of every term, but he gets a weekly schedule from each Director of Sport on a Sunday evening so he can plan on the Monday morning.

“It does change regularly with Cup runs etc – and they tend to do well in football as we are a big footballing school – but we work well to ensure it all comes together.

Our First team pitch generally has between 10 and 15 matches, compacted into a 10-12 week period.”

To cope with the huge workload Andy has a team of 13.

Making a mark

“There are two groundmen at the Prep school, with one classed as my Head Groundsman; there are two gardeners, with one classed as Head Gardener while, at the Senior school, there are four gardeners with a Team Leader and a gardener who looks after the Headmaster’s area. The remainder are grounds staff,” revealed Andy.

And while the quantity of sports turf is enormous, the quality required of it is reaching new heights.

“The Liverpool FC Camps UK is basing itself here for the summer. That will be the 14 to 18-year-olds, and they will be using it for training and player trials. They will use our houses for their accommodation.

This is really big for the school, and we are delighted to be hosting them,” said Andy who added that the South African Hockey team is also basing themselves at the school for the Commonwealth Games so that they can make use of the water-based pitch.

And when it comes to cricket, they are targeting a Derbyshire County Championship match later in the season. This comes on the back of Derbyshire basing themselves with the school during Covid for training purposes, as the English women’s team were using the County Ground in Derby.

“While they were here, I was able to produce the wickets they were looking for and talk to the players and the coaching staff about what they looked for in a pitch and what they wanted from a pitch. It was a really good learning curve for me and the team and allowed us to push forward with our pitch preparation skills.”

An example of which is the fact that they have just Koroed off one cricket square, something which had not been done for a number of years.

“That has really helped to refresh the surface,” said Andy.

Director of Cricket at the school is former England Test wicketkeeper Chris Read, who is just one of a number of high class coaches employed by the school. Martin Jones who coaches hockey is an ex-Olympian, while the Director of Swimming is none other than Scott Talbot, who coached Australian swimmers at the Beijing, London and Rio Olympics and was also the New Zealand national coach.

To support Andy in achieving what he wants, and what is required from the surfaces, the school has been extremely supportive and stuck its hand in the coffers to supply the equipment needed.

“We’ve got the right kit and I’ve been fully backed on what I want to do to raise the standards here and get us to first class levels.”

In the very near future, he will be signing off on in-house grinding equipment, something which will again assist in reaching the new levels of turf preparation, while they are also moving from fixed goals to portable goals, a project which should be completed by the summer.

“We use Harrod goals, supplied by Turfix,” said Andy.

That backing is all the more welcome given the costs hikes that have been so widespread across the industry, and, indeed, all our lives.

“The red diesel change has been a real shocker. It seems really strange to me that golf clubs can continue to use red diesel but schools can’t. We used to be £880 for a delivery but it has now gone up to £1,200 and we have four or five a year, so that is a huge increase in costs just in itself.

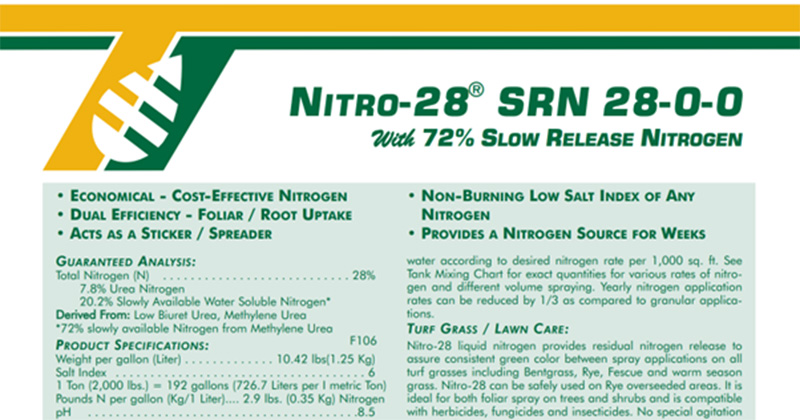

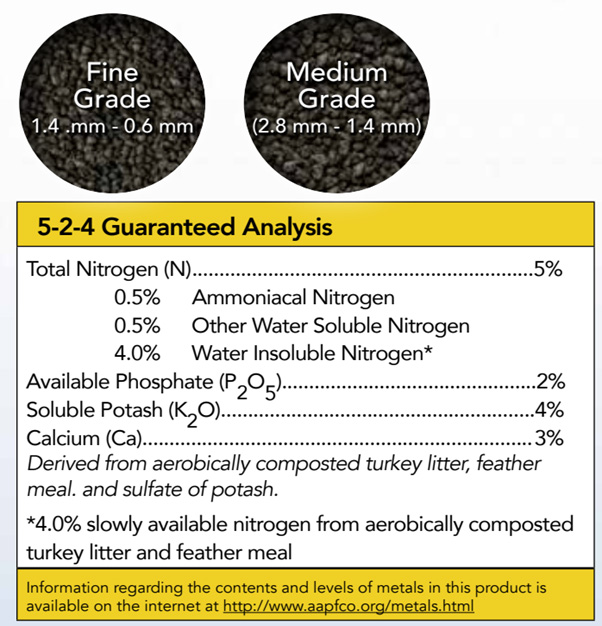

“Fortunately, I bought all our fertiliser before Christmas so we missed the biggest hike,” he revealed, adding that he uses Agrovista for his fertiliser and chemical needs.”

It all hints are difficult times ahead but for a man who waited 14 years to be given the opportunity, Andy is relishing all that his new position has in store for him.