Ballybunion GC Enhances Turf Maintenance with Foley

Ballybunion GC Enhances Turf Maintenance with Foley: Ballybunion Golf Club, located on the north-west coast of County Kerry, Ireland and steeped in history since its founding in 1893, is widely celebrated for its breathtaking coastal views and challenging yet rewarding links.

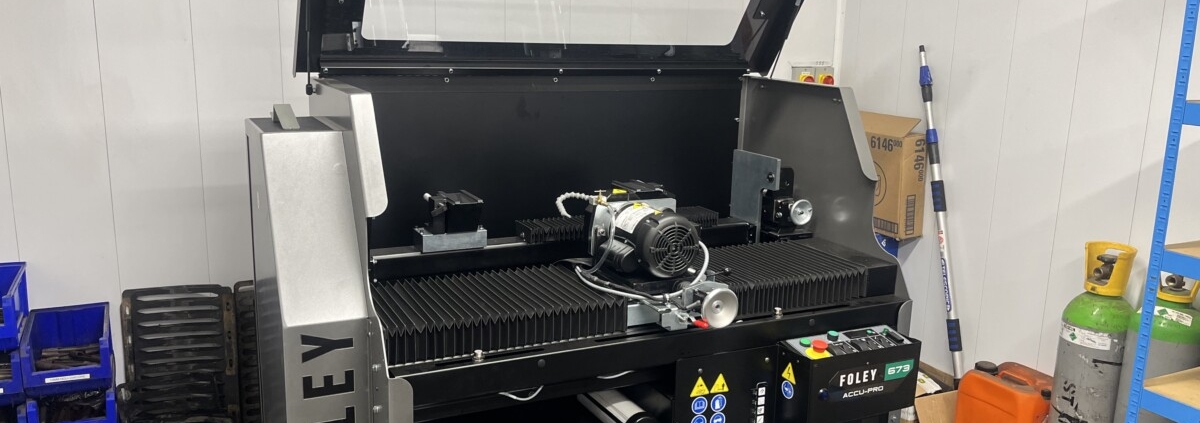

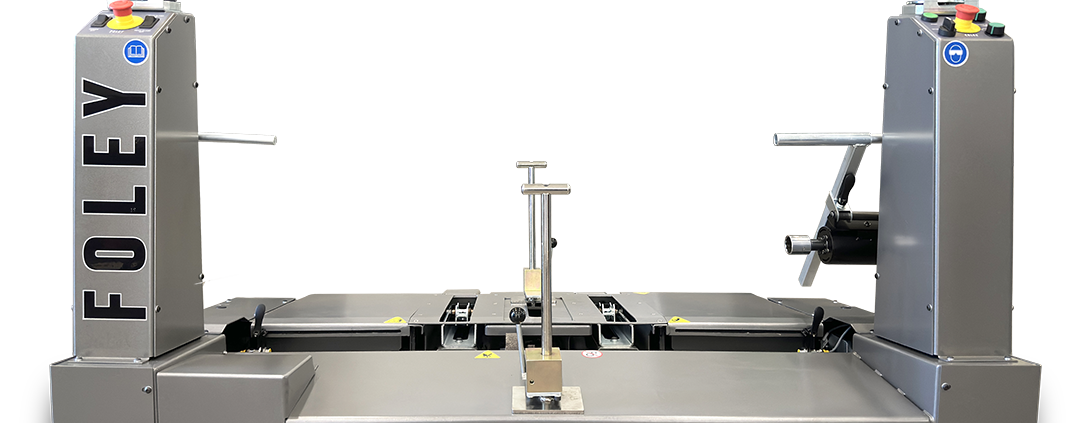

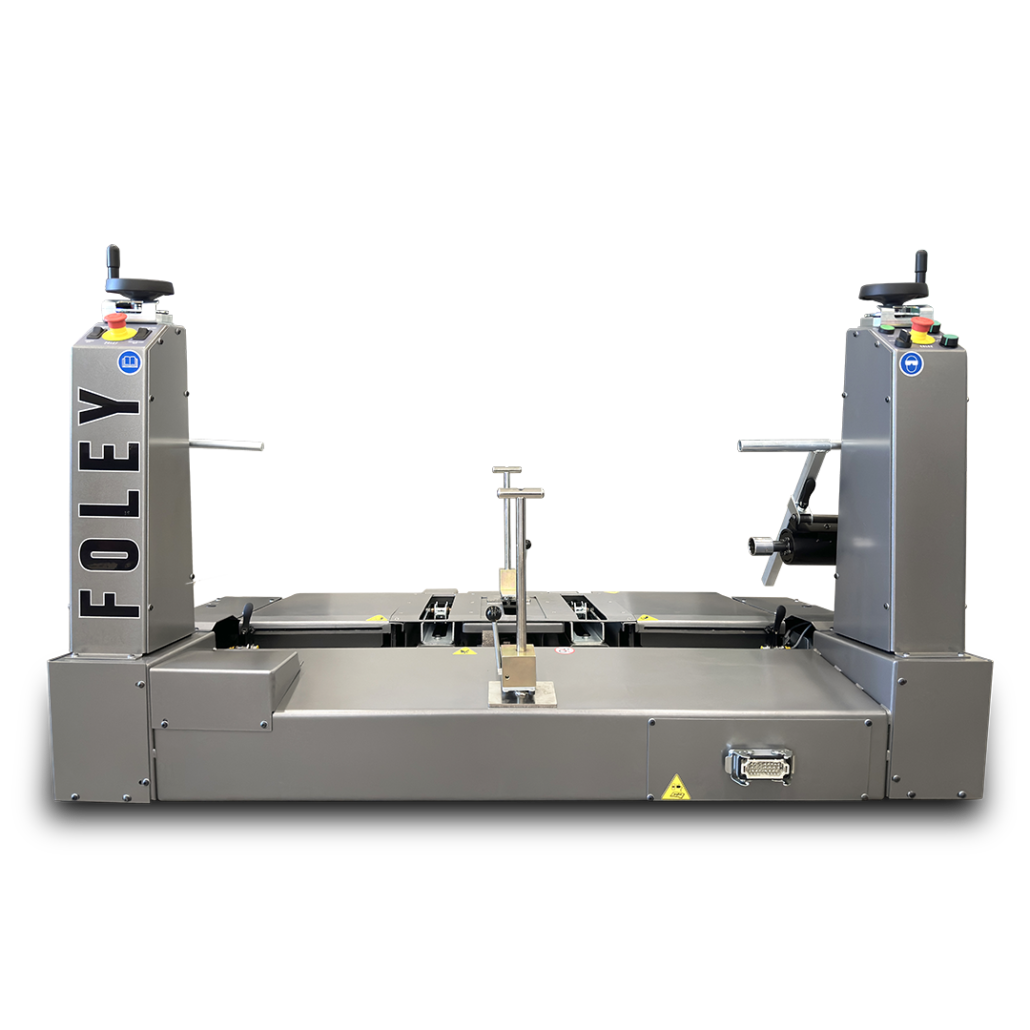

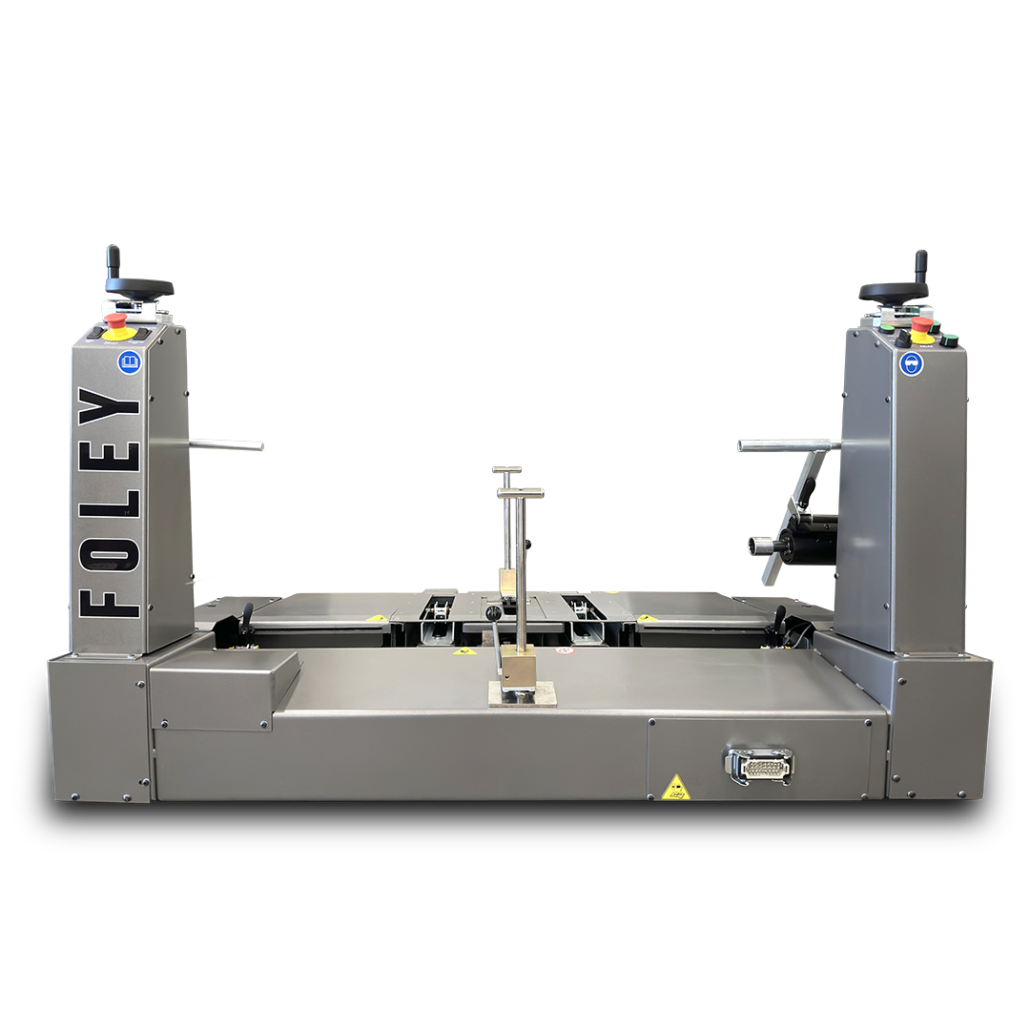

Over the years, the club has become a symbol of golfing perfection, attracting players from around the globe to experience its world-class courses. Continuing its tradition of excellence, Ballybunion recently acquired state-of-the-art Foley grinders, comprising a Accu-Pro 633 Accu-touch 3 control cylinder grinder with rear tail lift and an Accu Pro 673 bedknife grinder, to further elevate its turf maintenance standards.

Ballybunion GC Enhances Turf Maintenance with Foley

The decision to invest in Foley grinders was driven by Ballybunion’s unwavering dedication to delivering immaculate playing conditions. With such a large fleet size in regular use, the advanced automated relief and spin options offered by Foley grinders ensure that the reel’s edges remain sharp for longer, improving efficiency and playability.

Speaking on the importance of this investment, Course Manager John Bambury remarked, “At Ballybunion, we pride ourselves on maintaining some of the finest greens in the world. Our new Foley grinders allow us to achieve a level of precision and consistency that aligns perfectly with our commitment to excellence.”

Ian Robson, Managing Director of ProSportUK Ltd, distributor for Foley Company in the UK and Ireland stated. “We are delighted to have placed two of the latest Foley grinders into a prestigious club such as Ballybunion. We have had a relationship with the greens team at Ballybunion for many years after supplying and supporting the previous Neary grinders, and will continue to offer them assistance, whenever required going forward.

Ease of use and robust training were vital considerations in choosing Foley grinders. The intuitive design of the equipment provides Ballybunion’s maintenance team with the tools to keep the workflow going, while the thorough training ensures that team members can maximize the potential of this innovative technology.

The exceptional back-up service provided by Prosport UK and the Foley Company has been a key factor in this successful upgrade. According to John, “The support and service we’ve received have been outstanding. Being able to rely on Prosport UK and Foley Company helps us maintain the highest standards in turf management”

Foley Company is the world leader in professional reel and bed-knife grinders and delivers the most economical solution for all your spin and relief grinding needs. Designed for optimum operator safety and ease of use.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.