The loader market turns electric: The electrification of the non-road machinery market starts most strongly in the compact machine sector. Finnish loader manufacturer Avant Tecno Oy responds to the change by taking another significant step as a pioneer in the loader world.

The new third-generation fully electric Avant loaders have batteries that are manufactured at Avant Power’s new battery factory in Ylöjärvi, Finland. Full investments have been made to develop the unique battery technology. “In five years, half of the loaders we sell may be electric,” says Jani Käkelä, CEO of Avant Tecno and Avant Power.

The loader market turns electric

The compact machine market has been growing rapidly in recent years, especially in developed countries. Problems with the availability of labour and constantly tightening occupational safety regulations create more demand, to which multi-purpose compact loaders respond well.

Compact loaders can be used to work efficiently all year round, and their versatility is enhanced by a wide range of attachments. Another megatrend related to compact machines is zero emissions, which is becoming more and more prominent. This is due to the pressure created by general national and international emission targets to reduce coal use. In addition, small machines are often used partly or entirely indoors, and the work is naturally best-done emission-free for health reasons alone.

Avant Tecno has been developing electric loaders for four decades, and the company is now responding to the change with a huge development step. Avant Power, the newest subsidiary of the Avant Group, designs and manufactures batteries optimized for Avant compact loaders at the Avant factory site in Ylöjärvi, Finland. The new third-generation electric loaders have just entered production, and their lithium-ion batteries are the best on the compact loader market.

“Our own battery production gives us a unique head start in the electric loader market now and in the future. According to the fastest scenario, up to half of the loaders we sell could be electric in as little as five years. However, diesel loaders will still be needed for a long time, as some market areas will switch to electric loaders on a much slower schedule,” says Jani Käkelä, CEO of Avant Tecno and Avant Power.

The loader market turns electric

The world’s only loader manufacturer with its own battery factory

Avant made the decision to start its own battery development because there was not yet a good enough battery in the world that would be a perfect fit for Avant loaders. Under Avant’s roof, there were people with the expertise required for the bold project, and eventually, these experts formed the core team of the new subsidiary.

“Now, a solid foundation for battery production has been built through hard work. We have invested heavily in product development, and we also have partners with world-class expertise. The exceptional solutions in our battery technology bring many benefits to our customers, and we will be able to respond to strong international growth in the future,” says Mikko Piepponen, COO of Avant Power, who is also responsible for creating the new technology.

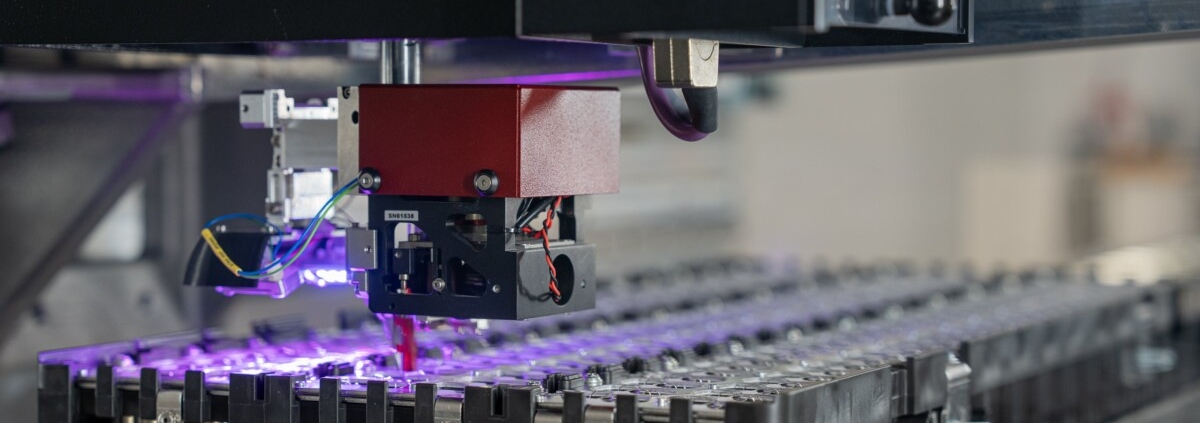

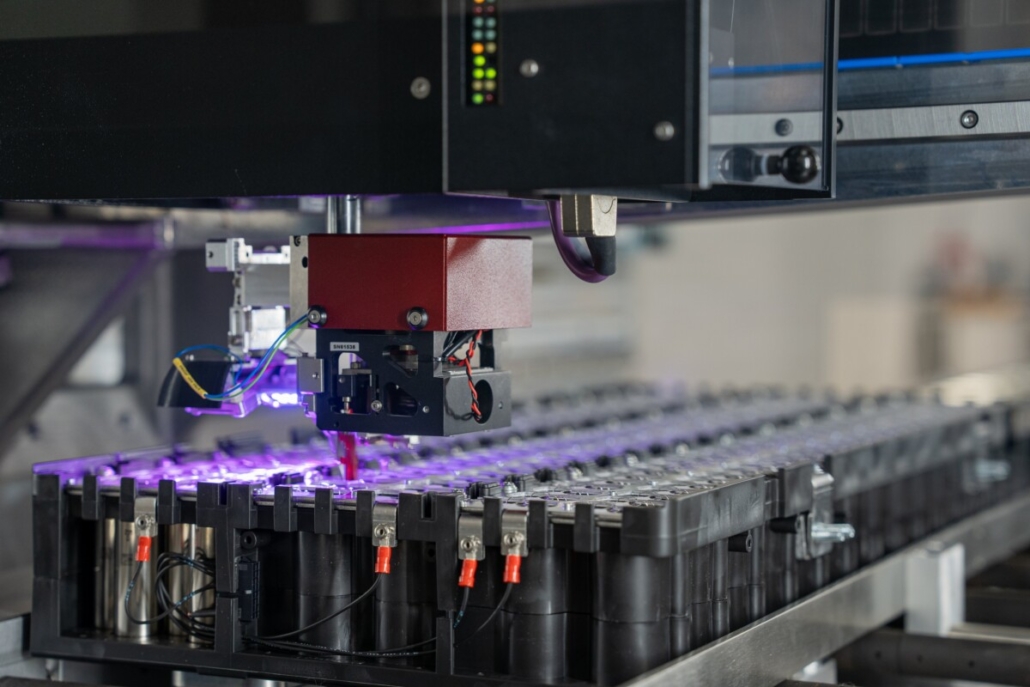

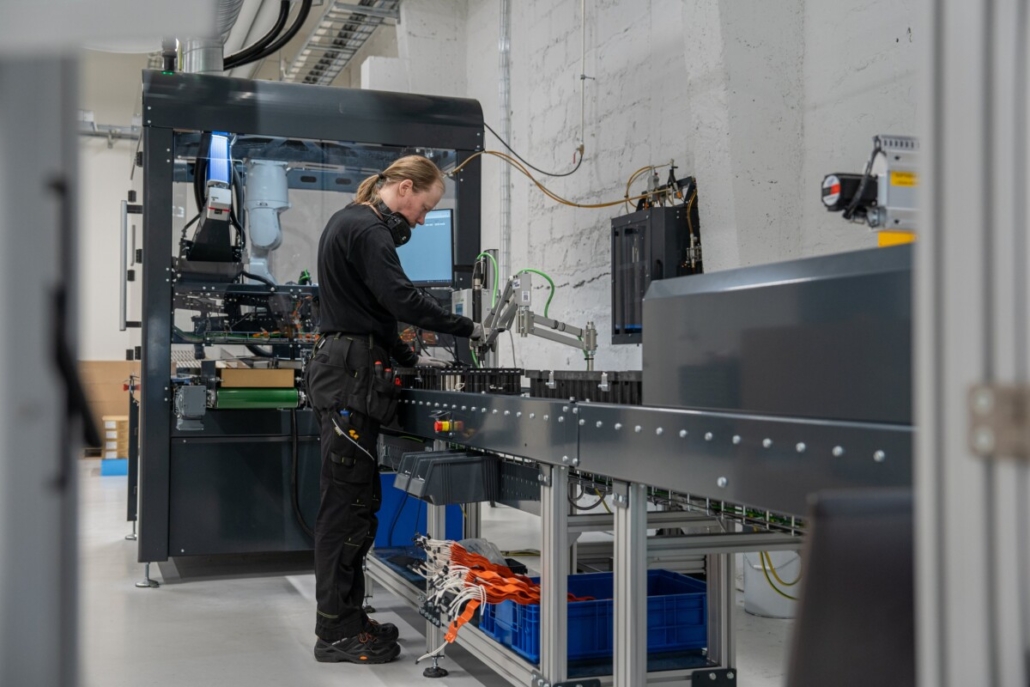

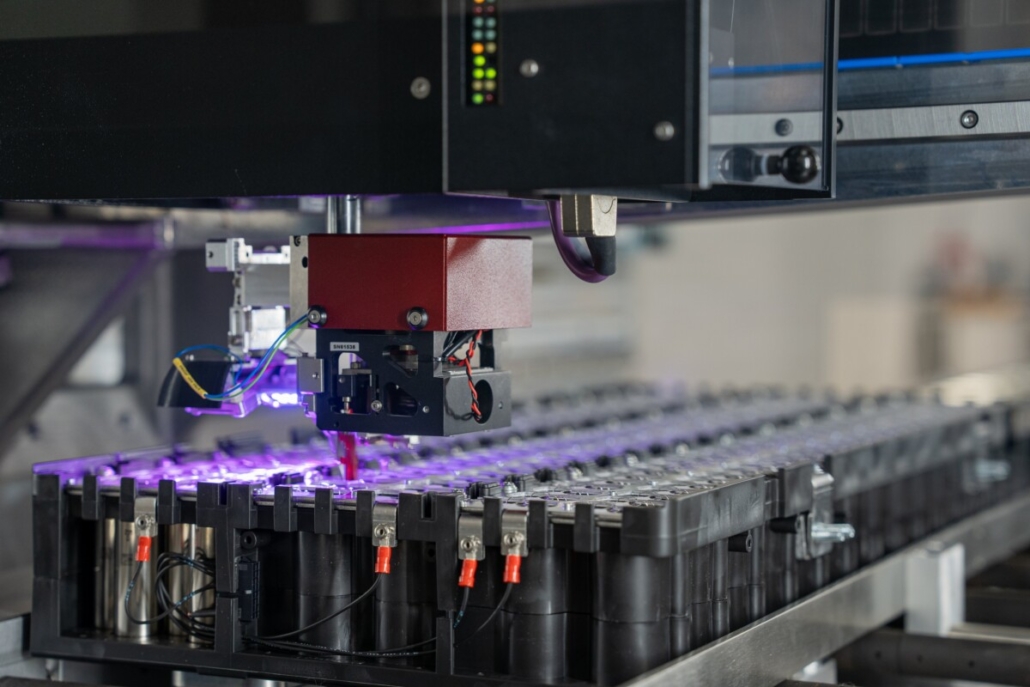

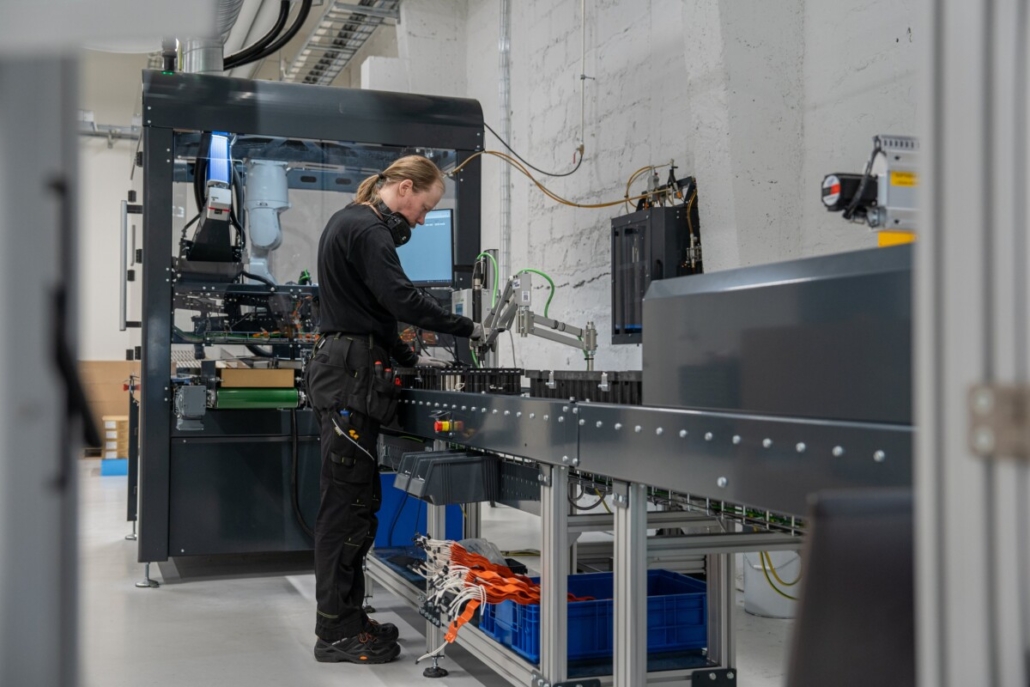

Avant Power’s current facilities have served as a production development laboratory, where battery testing and manufacturing technology have been fine-tuned. Both the new battery technology and the battery factory production line have been designed by Avant Power. The same goes for most of the production equipment, which is exceptional on a global scale. Since production and the product have been designed at the same time, the whole is as simple and uncompromising as possible.

“We have used the most modern possibilities in automation and developed the production line solutions ourselves. We started production at a moderate pace, and towards the end of the year we will increase it to full speed. Next year we will manufacture 700 to 800 batteries.

“The self-designed and implemented production line enables, above all, agility, and scalability. At the same time, all expertise related to batteries and loaders is under the same roof,” says Santu Tyynelä, Chief Design Officer at Avant Power.

Currently, batteries are manufactured on one production line, but another production line has already been ordered and its installation is awaited.

The best battery on the loader market

Avant Power’s globally unique Avant OptiTemp® battery technology further improves the working time, capacity, pricing, safety, durability, and lifespan of electric loaders.

The loader market turns electric

Thanks to immersion cooling technology, the batteries have excellent thermal management, which has long been one of the biggest challenges in battery technology, especially in mobile machines and equipment exposed to fluctuations in outdoor temperature. Avant OptiTemp® battery technology makes the operation of an electric loader more efficient than ever before, both in severe frosts and hot working conditions. In addition, the batteries have multi-level protection, which makes them very safe.

The operating time of electric loaders has now reached a completely new level. The new fully electric Avant e527 loader has a working time of 6 hours in optimal conditions, which is up to double compared to the previous Avant e6 electric loader. On a single charge, you can drive the new e-loader for 21 kilometres. The range is more than 60% longer than the range of the previous Avant e6.

Due to Avant’s own battery production, the new electric loaders are very competitively priced. “The loader battery is the largest single price component of the machine, and the price of battery cells is the most significant price component of batteries. With our own battery manufacturing and efficient procurement of battery cells directly from the cell manufacturer, we can significantly reduce the price of the loader. With our own company focusing on battery technology, we can also develop the battery for future needs in the best possible way,” says CEO Jani Käkelä.

New Avant e series available now

The fully electric loaders from Avant’s renewed e series – the Avant e513 (battery capacity 13 kWh) and Avant e527 (battery capacity 27 kWh) – are now in production. The domestic delivery time is about 10 weeks from the order. In export countries, the delivery time varies from country to country. More detailed information on delivery times is provided by importers.

For more information, please visit www.avanttecno.com/uk

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.