Deere dealers explore technology advances

Deere dealers explore technology advances: More than 50 John Deere dealers have been given advanced training on how greenkeepers can make the most of the latest technological innovations developed by the company.

Held at Golfpark Kurpfalz – a renowned German complex largely maintained using John Deere machinery – the event saw representatives from across Deere’s European network of dealers trained by experts from across the golf and turf division.

Deere dealers explore technology advances

Chris Meacock, Division Sales Manager for Golf and Turf, said: “Our innovation pipeline looks to improve every aspect of a machine’s performance and that covers many facets of a product.

“What’s changing fast is the opportunity to use technology and data to make the process of using a John Deere product more efficient and productive for our customers.

“This event was a chance for the dealer network to see all our precision turf technology in action, working together to demonstrate the advantages of GPS-driven accuracy.”

The training centred on the direct impact precision applications can have on reducing inputs while increasing accuracy and productivity through efficiency gains.

Dealers were shown how mowers and compact tractors equipped with Deere’s satellite-steering AutoTrac technology can reduce overlaps and fuel consumption. HD200 Progator sprayers were demonstrating their ability to place fertilisers and herbicides in exactly the right place, avoiding spraying non-target areas and wastage.

The advantages of accurately mapping a course’s tees, greens, fairways, bunkers and paths was presented using Starfire GPS receivers and dealers were given further training in how the data produced could be accessed and tailored for course managers using the John Deere Operations Center.

Sessions were also run on how OnLink – the cloud-based golf course management software acquired by John Deere in 2019 – automatically synchronises any machine and operator working anywhere on the course, allowing course managers to remotely create and assign tasks and meticulously manage equipment and labour costs.

“This training sets up our dealer network to be able to work even closer with golf courses who are looking to take their maintenance and management to the next level,” Chris added.

CROSSHEAD: Satellite-steering with AutoTrac

One of John Deere’s key strengths is its ability to adapt technology from other areas of its global business and implement it in professional groundscare.

GPS steering in agriculture has been hugely popular for over 15 years, but its application on golf courses and sports pitches is now starting to develop.

The John Deere AutoTrac system used on fairway mowers and compact tractors has the potential to deliver huge benefits.

Assisted steering leads to less operator stress and reduced overlaps or gaps, which positively impacts fuel consumption and productivity.

Lazer-straight lines and cut patterns are also easier to achieve by removing operator inconsistencies, even in low-visibility conditions.

“Boundaries and guidance lines can be stored in the John Deere Operations Center too, allowing the next operator to follow the same pattern,” Chris adds.

CROSSHEAD: Spraying with more accuracy

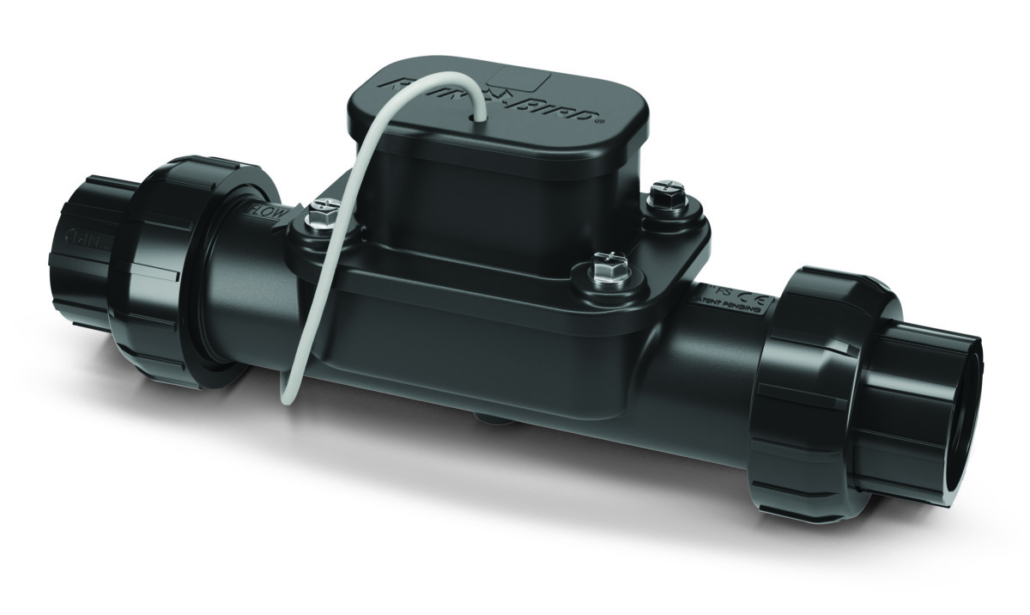

The cost of protecting turf from pests and diseases, and nurturing it with sufficient fertiliser, is a significant cost for golf courses.

Clubs are also under increasing pressure to ensure that chemical applications do not have any detrimental impact on the environment.

It’s been 20 years since John Deere launched its HD200 sprayer, which works in tandem with a Progator utility vehicle, but its relevance to today’s turfcare profession has never been greater.

Equipped with a Starfire receiver the machine has the ability to automatically turn on or shut off individual sprayer nozzles across the boom according to its position on the course – spraying around watercourses or the fringe of a green, for example.

Accuracy can be measured down to 2.5cm.

CROSSHEAD: Remote management with OnLink

OnLink technology delivers two clever modules; OnEquip which provides a real-time feed on the machines activity, such as run time, servicing intervals and idle periods, while OnLabor schedules work and assigns it to members of the team.

OnLink connects to machines to the Operations Center so data gathered can be used to plan and improve operation efficiency – each machine’s working hours can be balanced across its life cycle to reduce the cost of ownership. Mowing patterns, reducing the time required to complete work, can also be managed.

Alerts flag when maintenance is required along with owners setting geofences and curfews to stop the machine working outside of set locations or hours, increasing its security profile.

In the future the app-based OnLink hub will offer the possibility to plan for weather conditions, track the speed of greens and monitor soil moisture while also creating accurate budget forecasts.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.