GKB Vstrong impresses again

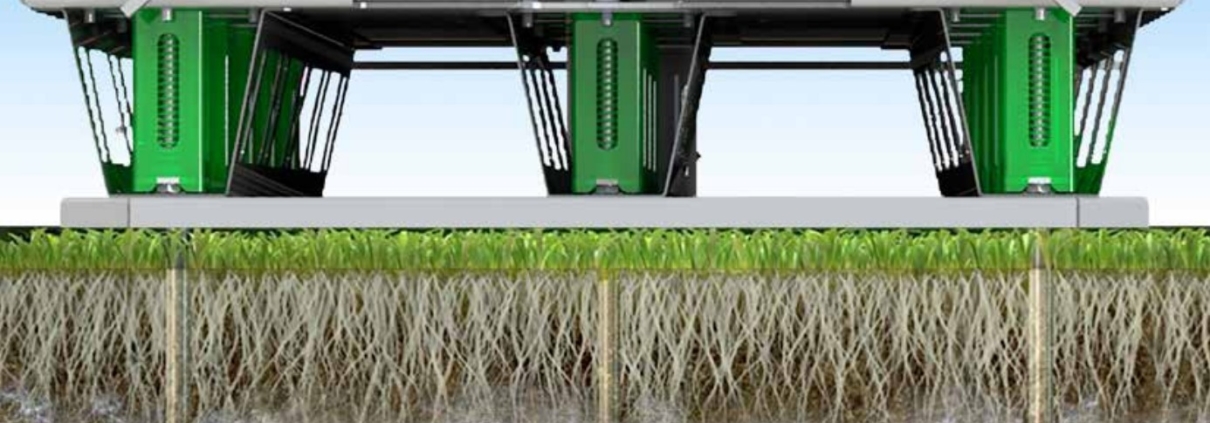

GKB Vstrong impresses again: Based in Woolpit, Suffolk and with over 35 years of experience and knowledge, Parkers Pitches added a GKB Vstrong to their range of robust and dynamic machinery, through GKB’s distributor Ernest Doe.

Parkers Pitches have a passion for sports pitches and knew the perfect partner to support their passion was the GKB Vstrong. The sports turf management company, run by hands-on Owner Will Parker, have been impressed with the performance of the machine so far, stating: “We pushed the machine very hard this Autumn renovation season with over 40 cricket square scarified in 3 directions.“

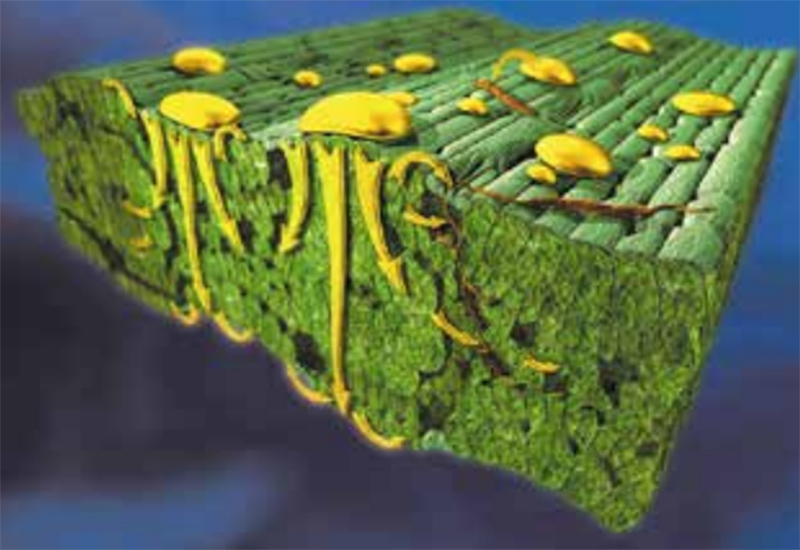

The beating heart of the machine is the CombiRotor, with its generically developed 3mm carbide scarifying blades. “The heavy duty nature of this machine has meant this year we have managed to scarify deeper and with closer blade spacings than in previous years, due to this we have seen great results with superb germination and coverage at all pitches renovated” Will adds. Thanks to the blades being rigidly attached to the rotor, the GKB Vstrong allows you to easily attain an operating depth of 5cm, not to mention it has a working speed of up to 10 kph.

Always completing high-quality work to improve and maintain surfaces and pitches the GKB Vstrong was a perfect match. Will explains “With the great results seen from a machine that is faster and cleaner than any we have previously used, we are in no doubt the Vstrong is the best machine on the market for cricket renovations and many other tasks.”

By scarifying and letting the material fly when you collect afterwards with a vacuum or a cut and collect mower, you are collecting less material. This leaves the soil behind and just takes the green waste off the top.

Parkers Pitches Vstrong features an optional collection box. This is specially designed for work on golf green and cricket squares.

For more on GKB Machines and their reliable and robust range of machinery for natural, hybrid and synthetic turf, please visit www.gkbmachines.com or contact Tom Shinkins on 07495 883617.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.