A Durable & Clean Cut, The Baroness Way!

A Durable & Clean Cut, The Baroness Way!: The main requirement for a mower is of course to cut grass, therefore Baroness always make this their primary objective when designing cutting units.

A Durable & Clean Cut, The Baroness Way!

The main criteria to consider during the design phase of a cutting unit is:

- A high quality of cut thus ensuring a healthy grass plant and a superior presentation.

- Simple and infrequent blade adjustments.

- Low maintenance costs.

The common denominator between all three of these is the material used to make the blades from, which in turn allows other design features to be exploited:

Relief Grinding

Relief Grinding is a process that not all reel mower operators support, usually due to bad experiences in the past and not fully understanding the science behind the practise.

As most reel mower operators will be aware, blade relief is where the trailing edge of a reel blade is ground away at an angle to reduce the surface area of the cutting tip. The thinner the cutting tip surface area is, the less friction will be produced between the cutting reel blades and the bedknife, and this in turn will reduce wear to the bedknife. This is important because the bedknife is the blade which will lose its edge first due to it being subjected to multiple reel blade passes per single reel revolution, and if you can keep the edge of the bedknife sharp then you will maintain a high quality of cut and a healthy grass plant.

To reap the maximum benefits from relief grinding the blade material used must be of a very high quality. If the blade was made of a soft material, then the very thin cutting edge produced by the relief grind process would wear away very quickly, and this would result in constant blade adjustments being required, which would then increase operator workload and frustration.

Achieving a hard blade is not just a matter of using a heat-treating process. Whilst heat treating will make any steel hard, it can also make it brittle, so to make a blade hard and strong it is crucial to use a suitable alloy coupled with a carefully controlled heat treatment process.

Baroness use a carefully formulated alloy of Nickel, Chrome and Molybdenum to make their blades from, and this very hard wearing and tough material allows the cutting edge to be relief ground down to just 0.5mm, thus keeping friction, heat and wear to a minimum.

Back-Lapping

Back-lapping is another process that not all reel mower operators support, and this is usually because the reels that they have been trying to back-lap are not compatible with the process.

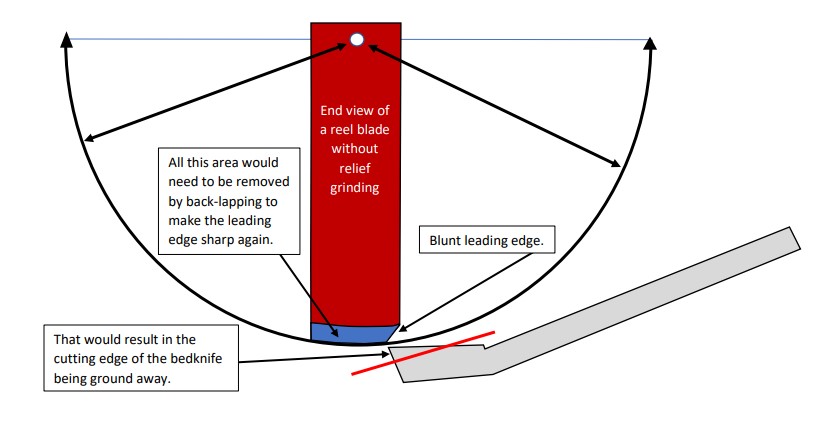

A reel blade which has not been relief ground will be very wide at the cutting tip, but when it becomes blunt it is usually just the leading edge of the blade that becomes rounded. However, to make this reel blade sharp again, all the material back from this rounded tip will need to be removed. To remove all of this material using back-lapping alone would take a long time, and by the time this material was removed, the back-lapping paste would have worn away the cutting edge of the bedknife, thus making the process counter-productive.

A Durable & Clean Cut, The Baroness Way!

If on the other hand the reel blades have been relief ground, then the cutting tip would be very thin and will therefore only require minimum material to be removed to make the reel blade sharp again, which could be done very quickly without wearing the cutting edge of the bedknife away. As the blade material that Baroness uses enables the relief grind to be taken down to a cutting edge of just 0.5mm, the full benefits of back-lapping are utilised.

A Durable & Clean Cut, The Baroness Way!

Therefore, relief grinding, coupled with a good quality blade material, is key to quickly and easily keeping your blades sharp at a minimal cost, which in turn will improve the health of your grass plant.

#LessstresswithBaroness

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.