Raising the bar: Scott MacCallum headed to Hertfordshire to meet James Bonfield, a Course Manager for whom a change of club ownership has been a real tonic and a chance to set new standards.

Finding out that your company has been taken over, or that you have a new boss to whom you will be answering in future, is an unnerving situation. You see it in all walks of life. Your face no longer fits, or you find that your name appears on the list of potential redundancies.

Raising the bar

It never ends well. Or does it?

James Bonfield, Course Manager at The Hertfordshire Golf and Country Club, found himself in that very position three years ago band went through all the anxiety and uncertainty that goes along with the territory. However, when we spoke in the ancient splendour of the mansion house around which the course flows, you could scarcely find a happier man.

However, there is no denying that the period before Elysium Golf Ltd, a company with no previous record of golf club ownership or management, was a worry.

“We knew that we were being taken over but didn’t have too much information about the people we would be working for or what their goals were – we knew they didn’t have a history in owning golf clubs. This is their first golf course and we didn’t know our position in their future plans. So, it was all up in the air,” recalled James.

What is never in doubt during these situations is that they inevitably become hotbeds for all sorts of rumours.

“In the months before there were rumours flying about. Everyone who was not working here seemed to have a direct line to the owner and knew what was happening,” said James.

“We were only going to be nine holes. We were going to be closed totally. We were going to be this. We were going to be that,” said James.

“We were only going to be nine holes. We were going to be closed totally. We were going to be this. We were going to be that,” said James.

Given that the land, north of London and in sight of the city of London itself, would be worth a fortune to developers, many of the rumours could possibly have carried some genuine mileage.

“The first couple of times that you hear it you think ‘Whatever’. Then, after we’d been hearing the same things for about six months, it got to some of the lads. I feel very fortunate that I still have half the team from 2019. My Deputy, my Mechanic and my First Assistant are still here,” said James, who stressed that he has no issues with those who left given the uncertainty of the times.

“You could say that we all took a chance and stayed, and we are very happy that we have. We have rebuilt team and added to the team.

We had six before the takeover and we are up to ten now – nine greenkeepers and a gardener. It is a sign of where we are moving.”

Raising the bar

However, they didn’t know that their coin had come up ‘heads’ until they arrived for work the first day under the new owners.

“On that first morning they had no idea what to expect of what they were going to be told. But then we found Simon Doyle from Troon Golf was there waiting for us.”

Troon Golf had been brought in for six months during the transition and to assess the skills of James and his team. A very smart move by Elysium.

“Simon gave us an overview of what would be happening,” said James

“It was good to have Troon here. They were the contact to the owner and vice versa. Simon just came in that first morning and put everyone at ease. When Troon walk in it’s a sign that they are not going to be closing it down soon. You don’t get Troon in for no reason whatsoever.”

It was also a sign that Hertfordshire Golf and Country Club was going to change for the better.

“We were not to be dealing with mediocre – we’re going high-end. And every decision since then has been based on that objective.”

Simon sat down with the team and said this is the plan. This is where the owner wants to head and we went off and went through everything.

“Lucky for myself and my background we had a good chat and he soon appreciated where we came from, our abilities and collective drive to make the courses as good as we could make it.

“It was helpful to be able to achieve our machinery needs, what we would need going forward, as the machinery had in the sheds as a result of the sale, wasn’t fit for purpose.

“He helped us to get a machinery inventory together and get it across the line with the owners and start getting into it so we can move forward,” said James, adding that it was good that people were investing in them.

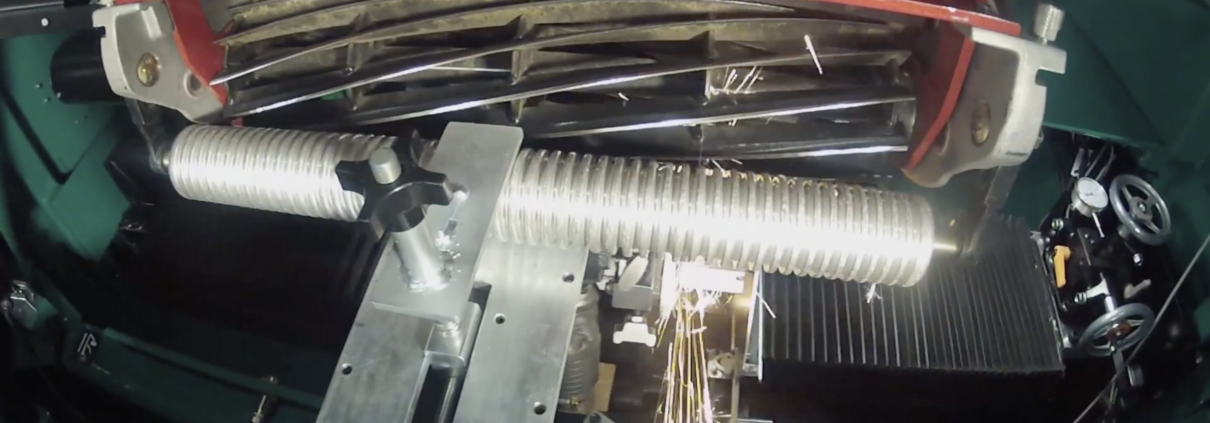

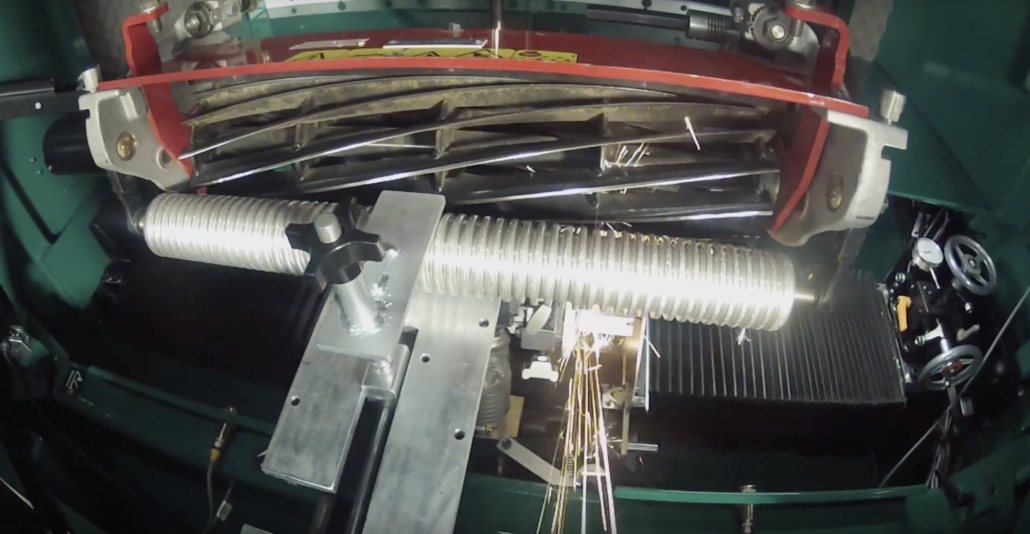

“The cost of the machinery fleet wasn’t cheap – Toro. And there were no corners cut.

Everything was Toro, other than a Kubota tractor.

“So that’s fantastic. Since then, machinery-wise, we’ve continued to add to it so we’ve got a fairway seeder, two Wiedenmann spikers – one for greens and one for fairways.

Also a trencher so we can do our own drainage works, and another tractor so that we would have more options. So we have got more and we are going to add next year.”

“Every year we continue to progress. It doesn’t always mean adding new machinery. We will not just get kit for the sake of getting it. But will get what we need to will make us more effective as a team and allow us to work more efficiently.

“I don’t want to waste the owner’s money. I don’t want him coming down and seeing a bit of kit that has been sitting around doing nothing for six months. That would kill me. I want him to come in and see that everything has been used and that it is all in good nick. That way we will build up trust.”

Having been given the tools there must be pressure to achieve great things and meet the new found expectations for the golf course.

“This is going to sound big-headed but it’s not meant to be,” said James. “My Deputy, John Hart, and my First Assistant, Karl Vincent, and I have always tried to be better than where we were.

“We’ve always tried to push this place forward. We play a lot of golf at other courses. All the team play from +3 to me at 16 handicap we know what better looks like and, more importantly, what it feels to play it.

“The frustration wasn’t quite having the resources to get to where you felt it could be. That is not to fault the previous owners, that’s just the market we were in at that point.

We are not in that market any more.”

How that manifests itself involves doing exactly what they’ve been doing but adding to it.

Raising the bar

“Areas we wouldn’t have thought about doing in the past – we can dress tees now and so we discuss if we are to be doing it what do we need? We need to overseed, for example. So we need to build it all into the budget.

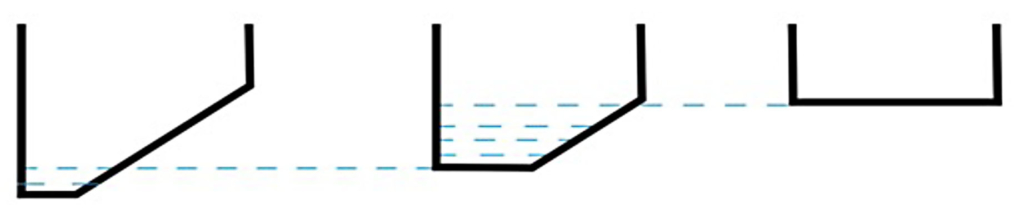

“And the same for approaches, because we’ve always grouped tees and approaches together. Then it was how could we improve the course, so we’ve added swales and run-offs round the greens, because we’ve got really nice undulations.”

All this work, as soon as the team were let off the lease, combined to prove to Simon, and ultimately the owner, that James and the team could be left to get on with it.

“Simon is a very knowledgeable guy and runs a lot of golf courses and after about three days he realised that we were confident in doing what we were doing. We were speaking his language. And that got fed back to the owner and he then has more faith in what is going on.

“We love this place and are always thinking about what we can do to make it better.”