BASF launches Nemaslug 2.0 for improved slug control

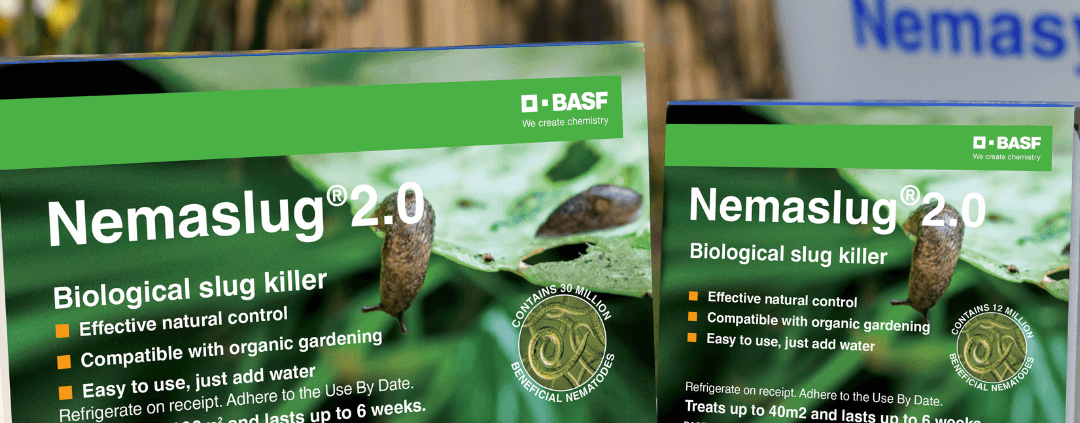

BASF launches Nemaslug 2.0 for improved slug control: Leading pest control solutions manufacturer, BASF, has launched a new and improved version of its hugely popular and effective biological slug control treatment, Nemaslug. Nemaslug 2.0 provides all of the protection and high efficacy rates of the original product, but has additional benefits, too.

The improved product has been produced following the discovery of a new species of nematode – Phasmarhabditis californica. This species of nematode can be packed at much higher concentrations, so the same amount of effective nematodes can be stored in a smaller pack, which has helped BASF to reduce the plastic packaging of its slug control solution by half. More efficient storage as well as fewer containers being needed to transport the product, further reduces the carbon footprint, which aligns with the company’s sustainability goals and its aims to provide a greener option for slug control.

BASF launches Nemaslug 2.0 for improved slug control

On top of this, improvements made to production has led to a further reduction of over 20 tonnes of CO2 emissions a year, while the UK-based facility negates the need for carbon-heavy international shipping.

Nematodes occur naturally in the soil and seek out and kill specific target pests. They attack the pest by entering its body and releasing bacteria that quickly and effectively kills it. The nematodes then reproduce inside the dying pest and release a new generation of hungry nematodes, which disperse and search for further prey, protecting the area for up to six weeks.

By tapping into the benefits of this naturally occurring friend of the gardener, soil can remain healthy, while ensuring slugs are conquered and plants protected.

The company is dedicated to investing in research and development to ensure that it is able to provide the highest quality nematodes to gardeners, and is keen to create a product that will appeal to those looking for a greener option for slug control. It is this dedication to research and development that has enabled the discovery of a new species of nematodes to use in its Nemaslug product.

This small but powerful box of fresh nematodes can be delivered directly to a gardeners’ doors throughout the growing season to ensure that slugs can be controlled effectively by harnessing the power of nature.

To find out more about how nematodes work, take a look at this short video – https://youtu.be/JHNG1KSluh0

For further information please visit https://www.nemasysinfo.co.uk/ and follow basf_nemasys_uk on Instagram.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.