Meet the Grower

Meet the Grower: Turfgrass Growers Association – Meet the Grower

Stephen Edwards, Inturf

How long have been growing turf for? (including any history facts/ old pictures)

We have been turf growing for 36 years, and it all started with 50 acres, we now produce well in excess of 2000 acres or more than 800 hectares in new money. My father Derek Edwards worked with another turf growing company in the late seventies and early eighties, and helped shape the face of the cultivated turf industry into what it is today, but wanted to carve his own path in the sportsturf World. This was extremely successful, customers included; the All England Lawn Tennis and Croquet Club (AELTCC) in Wimbledon, Wembley National Stadium, and many Famous Golf Courses. Since then, we have mechanised and now supply nearly all of the national DIY chains, various Building Merchants, and many Open Championship Golf Courses. We also grew turf in Northern France in the 1990’s from where we re-turfed the Parc des Princes, Paris using our patented ‘turf tile’ and ‘thick-cut big roll’ systems; pioneering systems which were adopted by a handful of other turf growers across the UK and Europe and helped numerous football clubs re-turf during the playing season. We also introduced the ‘standard big roll’ turf format in 1991, and by 1992 no other turf grower anywhere in the world was using this so ubiquitously as Inturf!

Meet the Grower

The Team (tell us a bit about your team and what they do in your business)

We have a very dedicated team at Inturf, the majority of whom have been with us for many years, 30 years plus in a few cases, and we are hiring new recruits regularly to keep pace with an inexorable increase in demand for our turf. As the business grows, we will require more and more staff to drive the latest technology and to occupy the growing office.

Employee training and engagement are key markers to retain staff and for success, and we leave no stone un-turned in the respect. Valuing staff is a priority for Inturf.

What is your proudest achievement (within turfgrass work that you have done)?

There are many, however, I think the proudest moment was re-surfacing ‘Centre Court’ at the AELTCC in August 1997. My brother (Alex) and I completed this work behind closed-doors for the club during a very long hot summer. Nearly every court had been re-surfaced using our custom-grown-turf service (another first in the turf world), either before or following the centre court re-turf… to my knowledge, this had not been undertaken before or since our time working with the AELTCC, which spanned circa 20 years.

Why do you love producing turfgrass?

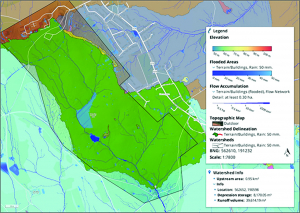

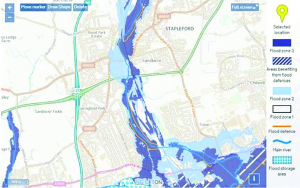

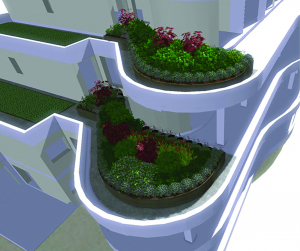

Most importantly, turf is good for our planet… socially, environmentally, and economically and generally speaking the people who operate within the industry are down to earth and helpful. We have an amazing manicured 2000-acre plus garden too, so we benefit from the abundance of positive health benefits turf offers – for instance; it’s noise reductions qualities, flood defensive applications (it reduces water run-off), it has a high efficacy of carbon capturing, in fact, better than any tree per square metre of plantation and turf really does have the ability to calm even the busiest of minds… just try walking on your natural lawn in bare-feet… wearing footwear is an exclusively human characteristic!

What is your favourite piece of equipment or machinery on your turfgrass farm?

It has got to be the turf harvesters, albeit they are temperamental, they cut 4 million square metres of natural turfgrass every year, and without them, we simply could not grow the business in the way we have… hats-off to the Americans for this technology!

If you had one piece of advice for turfgrass customers, what would it be? (can be laying tips, watering tips, choosing the right turf etc)

Prior to turfing; get the ground preparation right by following our ‘online’ advice and easy steps or call a trusted landscaper, lay the turf as quickly as possible (preferably on the day of delivery) and water it well until it is rooted to approximately 100 mm or 4 inches and for no longer than 28 days.

What do you think is the biggest challenge facing the future of the turf growing industry?

In the short-term, artificial turf has become more ubiquitous and the money and marketing behind the carpet manufacturers is matchless. That said, I think that in the medium to long-term, we have to be careful not to ‘over-cook’ the current high demand for natural turf by using quicker growing methods, such as using plastic netting, which isn’t good for the environment and will only serve to offer the artificial turf producers more ammunition and indeed mitigation against using natural turf in the future… oh, and another global pandemic, because next time, we might not be so lucky!

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.