Nitrogen… more than a number on a bag: I recently asked someone what they would do if they wanted to feed their turf for a long period of time from one application of fertiliser? The answer given was that the higher the number of N on the analysis, the longer it will last…

So will the analysis, 21.0.0 last longer (longevity) than an 18.0.0? I’m afraid if you answered yes then, well… you aren’t right or wrong, you just don’t have enough information yet. Let’s explore the rationale behind that and why it is important.

I’m sure everyone reading this understands the cost of turf nutrition has significantly increased in the last twelve months! For that reason, I wanted to take this opportunity to bring us back to basics. I want to refresh everyone on the importance of correct selection when it comes to Nitrogen Sources (N), where we find this information and why it really is the most important thing to understand to get the maximum value and performance out of your fertiliser.

The Main Nitrogen Sources for Turfgrass

Nitrogen is, by a long way, the most important and influential input we provide to our turf. It provides the building blocks of plant growth and development. Due to surface usage and necessary but stressful maintenance practices, we often must supplement our soils with Nitrogen based fertilisers to help our turf grow and perform. These fertilisers come in many shapes and sizes. I have set out below, the basics and what to expect if we apply them. However, if you are interested in more detail, I encourage everyone to research it, in particular, the Nitrogen Cycle, and how each form of nitrogen behaves in respect to it.

Disclaimer: I have selected what I believe are the most common sources of Nitrogen used in turf. I fully accept there are others but to keep it short and simple I have chosen the majority.

- Soluble Plant Available Nitrogen (Synthetic/Mineral)

These are water soluble forms of nitrogen that, when applied to the turf, are immediately (or almost immediately) available to the plant. Typically, this source is most useful when soil temperatures are low as microbial activity is required for other N sources to be broken down to available forms for the plant. Nitrate, (and when conditions allow, Ammonium) are the forms of Nitrogen taken up by plants and can come in many substances such as Ammonium Sulphate or Calcium Nitrate. Each have additional affects due to their components. i.e., ammonium sulphate also contains 24% sulphur and has an acidifying effect on the soil. Nitrate won’t last long though, due to its solubility and negative charge, it quickly leaches through the profile. Expect these forms to last 2-4 weeks depending on conditions and soil type.

Urea in its pure form, is a water-soluble form of N that, in warmer conditions, is very quickly made plant available as it requires the activity of soil microbes to convert it to plant available ammonium N. For this reason, it can be unpredictable in spring, and it is commonly used in summer/autumn fertilisers. Therefore, although volatilisation (loss of nitrogen as ammonium gas to the atmosphere) is slower in cold temperatures, if urea cannot be quickly converted to ammonium carbonate a significant portion can be lost to the atmosphere, an expensive mistake in the current economic climate. Urea is also popular as it makes a fantastic tank mix partner due to its extensive hydrogen bonding (highly soluble). Expect 4-6 weeks longevity from urea (depending on conditions) with it taking slightly longer to show a turf response than say, ammonium sulphate. It is rarely applied to turf in uncoated granular form due to its high salt index increasing the likelihood of scorch/salt stress.

The problem occurs on labels (if detailed), where any urea, regardless of the form, is referred to as “UREIC”. As we will find out, this can mean many different things.

- Synthetic Nitrogen (Slow Release)

Methylene Urea. A similar story to regular urea by which it requires the action of soil microorganisms. However, the production process creates a variety of longer chain molecules. This provides a predictable, slow, longer-term conversion to plant available N thus giving an even growth pattern. This makes them very popular in turfgrass environments where predictable growth patterns are important for performance, such as golf greens and sports pitches. Depending on the formulation and amount of MU, expect anywhere between 4-12 weeks longevity from these fertilisers. It is a very safe, low salt N source, available in both liquid and granular forms.

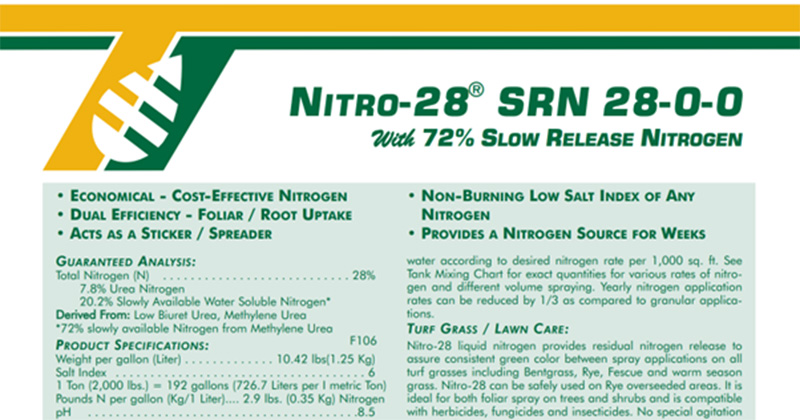

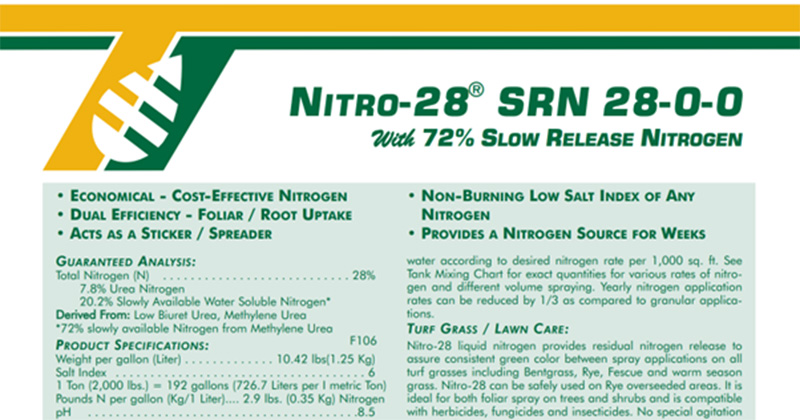

Thanks to its advanced production process, AGS Growth Products Smart Nitrogen™ contains more longer carbon chain molecules than other methylene urea molecules meaning it provides superior growth predictability and longevity (figure 1). Growth Products also pride themselves on providing end users with every piece of information they need by producing some of the most detailed labels on the market. This helps to ensure turf managers achieve the desired outcome with their fertiliser application (figure 2). Labels are not always this clear, they can be very vague, only stating the analysis. If this is the case, speak to your supplier and find out exactly what is in your fertiliser, be it granular or liquid.

Figure 1: The release curve of Growth Products Smart MU vs standard Urea based products. It provides a longer, more predictable release of N than regular Urea.

Figure 2: An excerpt from Growth Products Nitro-28. This is just a small amount of the detail printed on our labels. Many other products will not provide this information, but it is important you know it.

- Organic Nitrogen (Slow Release)

In a fairway situation, where clippings are not removed, organic matter provides most of the nitrogen for turf growth. Mineralisation takes care of excess organic matter, converting it to plant available N. However, in managed turf, particularly where clippings are removed, we may wish to provide supplemental organic nitrogen.

Organic fertilisers should be from materials derived from a living (or previously living) source, such as plants and animals. Be careful, this is a common place where cheaper mineral fertilisers can be passed on as more expensive organics by including small amounts of organic nutrients. The E.U. has some fairly lose rules when it comes to classification of organics. For example, to be classified as an Organic Solid, the product must contain a minimum of 15% Organic Carbon. To be classified as Organo-Mineral Fertilisers, Organic Carbon should be a minimum of 7.5% and Organic Nitrogen greater than 0.5%. Very easy to see how many so-called “organics” are not what they seem on the surface.

Granular organic nitrogen sources, such as Sustane, generally take between 4-8 weeks to breakdown leaving behind valuable soil building organic materials among other benefits that are extensively documented. They are also available in liquid forms. However, organic liquids are water soluble nutrients derived from organic sources (such as animal waste), therefore you extract the nutrients and leave the other valuable organic materials behind. They do not require the level of breakdown via microbial activity and have less beneficial effects on soil health.

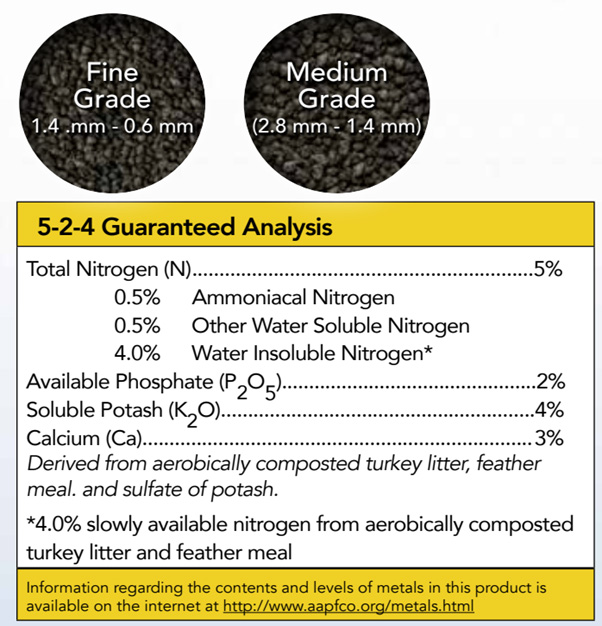

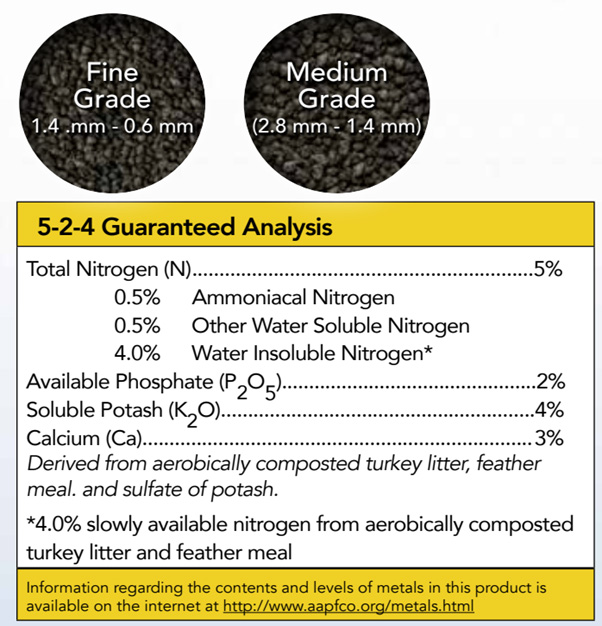

When it comes to organic fertiliser, make sure you read your labels, with any luck they will clearly state the percentage of Water Insoluble Nitrogen (WIN: This is your true organic part) and provide the organic source. For example, Sustane, contains mainly anaerobically composted turkey litter to supply the organic nutrition to the turf. The percentage of these are always clearly stated on our labels (Figure 3). Don’t be fooled here. Read your label and make sure you are happy with the amount of actual organic you are applying. If it’s not on the label, ask your supplier.

Figure 3: Guaranteed Analysis of Sustane 5-2-4. Detailed information is so important when it comes to Organic Fertiliser.

- Controlled Release Nitrogen

There is then a whole host of controlled release Nitrogen sources. Only available in granular form, meaning they are usually not feasible for fine turf, they consist of materials such as resin or polymer coated urea prills which rely on moisture, temperature and/or microbial activity for release. The most useful characteristic of these fertilisers is that release patterns can be long-term and predictable depending on the type and thickness of coating used. This is a popular choice for areas of turf that need regular nutrition without the ability/necessity to be applying regularly. Products range from 2-6 months in longevity and should come with a guide from your supplier on how long you can expect it last. Again, with urea-based products, the label is unlikely to help as it may all be stated as “UREIC”. This does not give us an accurate picture, there should be multiple grades of coated urea that help provide a smooth nitrogen release curve over the specified time. This is where supplier information is essential, make sure to ask them how the controlled release urea is formulated, as often a timescale in a catalogue can be misleading. This will ensure you meet your goals when it comes to long term, minimal application, turf nutrition.

Summary

I hope you can all see the importance of knowing your nitrogen source. Depending on your turf nutrition goals, we quickly start to see where proper selection fits in. Understanding how the source of nitrogen used will interact with the soil and therefore, the plant, is extremely important. If you are looking for a fertiliser that will last 2-3 months, then understanding that a product containing mainly ammonium sulphate won’t do the job. Similarly, if you are looking to give your turf a kick in spring then it would be a good idea to avoid anything containing too much urea or organic nitrogen. Whilst we can normally rely on suppliers to guide us, it is an essential piece of information that all turf managers should be aware of and regularly reviewing. Keep in mind that most fertilisers contain a blend, or formulation, of multiple N sources depending on the desired outcome.

A little on the underlying agronomics

I could go on about the intricacies of turf nutrition all day! I won’t. However, I would like to leave you with a parting piece of advice when it comes to your soils and nutrition. Get your pH tested! pH, or the acidity or alkalinity of your soil, plays a huge part the efficacy/availability of your nutrition and in turn the grass species that will grow favourably. Because of the way we maintain turf (particularly the use of fertilisers containing ammonium salts), we slowly (sometimes quickly) lower our pH. If acidity increases too much, availability of nitrogen, phosphorus, calcium, potassium and magnesium decreases. This also increases availability of toxic elements such as aluminium and manganese. Below pH 5-5.5, our desired grass species may start to show increased levels of stress. pH monitoring is important to all turf surfaces but is particularly important in sandy rootzones where pH changes quickly due to low CEC. Low pH also has a negative effect on our soil microbial activity thus further decreasing the efficacy of our nutrients that rely on them to breakdown nitrogen sources not immediately available to the plant.

So, absolutely, study your fertiliser labels/information and make sure that what you are buying matches your required outcome. But ultimately, if pH is not in the correct range, you could be missing a big piece of the puzzle. AGS believe in providing the very best customer service. We are happy to provide soil samples, including pH, free of charge. Contact us today if you would like a visit from our in-field technical team.

In conclusion, to go back to the question I asked at the start, we still don’t know if a 21-0-0 will last longer than a 18-0-0. The analysis (N-P-K) is a necessary piece of information when it comes to calculating the number of units applied, still an important exercise, but not the full picture. What we should be doing is reading our labels and asking our suppliers for more information. Then we can sit down and work out exactly what we want, and expect, from our Nitrogen inputs. This will help us make informed, agronomic, and economical decisions about the nutrition we apply to our turf, and hopefully squeezing every penny (Unit of N) as far as it will go.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.