A Toro Stitch In Tine Saves Nine…

Nine reasons why choosing the right tine is so important

Nine reasons why choosing the right tine is so important

Of all the management practices used to maintain healthy turf, it can be strongly argued that professional aeration has become the most valuable. Here Reesink Turfcare, exclusive UK distributor of Toro Parts, lists the top nine reasons reasons why choosing the right tine is so important for effective aeration.

Relieving surface or deep compaction, improving drainage, controlling thatch, and managing high temperature stress by increasing gas exchange, all require different skilled approaches or methods of aeration.

From coring, using hollow tines, solid tine aeration, slicing or spiking, water injection cultivation, deep tine aeration, and ‘linear’ aeration, there are certain considerations that can make the process easier and more efficient. Here we list the top nine we think will save you time and money and it all comes down to the parts you choose:

1. Tine quality

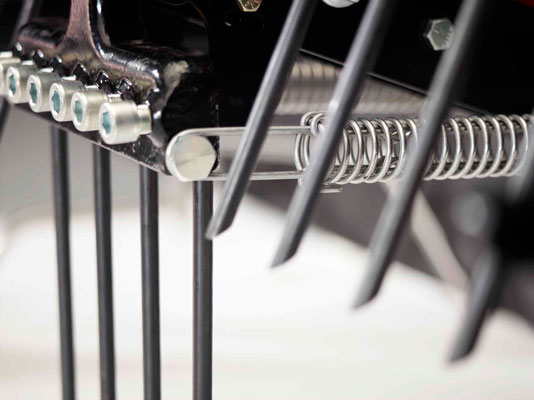

It’s now a lot more than just forking holes into the ground. Successful aeration is as much down to the quality and condition of the tines as it is the machine. In order to maintain the turf’s good health, it’s vital to ensure the very best equipment and parts are to hand. Toro tines are made through combining a strong alloy with a unique heat treatment process and a long-lasting tungsten carbide blend tip, resulting in a finished product that provides maximum strength and resistance to wear.

2. Hole quality

Clean-cut holes are important for a speedy recovery and the best way to ensure the speediest of recoveries is with tines that boast sharp edges and smooth sides. Michael Hampton, turfcare parts manager at Reesink Turfcare, says: “Toro tines are designed to produce precise consistent holes for fast turf recovery, a smooth finish and quick return to play.”

3. Inferior or spurious tines

Using inferior or spurious tines in a bid to cut costs can, in fact, cause operators to waste both time and money in the long run. Replacing broken or bent tines frequently, unclogging cores while on the job and collecting awkward core debris are all common side effects of will-fit parts and having to repair damage post-aeration is not only time consuming but leads to slower recovery and return to play. Put simply, “More man-hours and money are wasted cleaning up after inferior tines and buying and applying replacements, it’s just not worth it!” says Michael.

4. A perfect fit

Engineered and designed to fit the entire Toro ProCore range and get the best results from an aeration programme, choosing Toro tines ensures the perfect fit. Easily snapping into place or bolting on, when using Toro tines everything is aligned perfectly so nothing operational suffers when in use. Choosing will-fit tines can lead to poorer quality holes or wear to the machinery that is avoidable. As we know, fiddly ill-fitting parts waste time and effort, too.

5. Choice

Toro has a tine to suit every application. In fact there are over 150 tines to choose from meaning that no matter the turf application, soil situation or season, there’s something for everyone, guaranteed. Understanding the different tine options is important, you may be missing a trick to further improve the health of your turf if you’re just using, say, standard solid tines. Ask your Toro dealer or service centre about tines and what choices might be better suited to your specific applications.

6. Increased productivity

Regular aeration helps to keep the grass healthy, recovering from root compaction issues quicker, and with genuine Toro tines you can be assured of a tine that is designed to last three to four times longer than standard tines. This increase in longevity, not only means long-term dependable aeration with better soil, drainage and nutrient performance, says Michael, but “makes better use of your machinery maintenance budget too.”

7. Improved performance

Timing is vital when it comes to aeration – you’ll likely know when that is for your surfaces – and it is important not to be let down in the middle of the aeration programme. The tough design of Toro tines, including durable brazed tip joints that ensure a strong bond with in-built resistance to separation and breakage, importantly help maintain consistent aeration depths and reduces costly change-out and associated downtime.

8. Planning

Aeration schedules vary depending on soil type, budgets, resource, climate and usage and can be a balancing act for greenkeepers and groundsmen to ensure the health of the soil without disrupting play. Rest assured though, even if not stocking up, buying urgently required genuine Toro tines guarantees your timings and schedules need not be disturbed should there be a sudden need to make a replacement…

9. Service

When you need new tines, you get second-to-none parts back up with Reesink Turfcare. Reesink currently holds 15,000 Toro items available for delivery at 24 hours’ notice pretty much anywhere in the UK and 12,000 fast-moving lines are housed at the European distribution centre in Belgium with 48-hour availability. If all else fails, a 72-hour trans-Atlantic airfreight service comes into action calling on parts held at Toro’s Minneapolis manufacturing base. This is all at no extra cost to the customer and ensures downtime is kept to a minimum.

To stock up on tines or for more aeration advice, customers can get in touch with their local genuine Toro parts dealer or service centre.

Learn more about the products included in this story by visiting http://www.reesinkturfcare.co.uk