Wembley creates recyclable pitch process

Wembley creates recyclable pitch process: Wembley Stadium has staged some of the nation’s most memorable moments of the last century, but now the hallowed turf of the national stadium is set to create its own piece of history.

Wembley Stadium connected by EE has developed a unique new process to make its famous pitch 100% recyclable. The project is believed to be a first in the world of football.

Wembley creates recyclable pitch process

It is the result of a meticulous two-year plan to find a suitable solution to recycling modern-day football pitches, which are a hybrid of grass and synthetic plastic.

A large amount of professional playing surfaces in today’s game contain plastic to make them more durable. Hybrid pitches have become popular because they offer increased reliability in variable weather and can be used more for multiple purposes.

However, the recycling of old hybrid pitches has been a challenge. The plastic contained within the hybrid pitch means they do not break down naturally, and the majority of old pitches are sent to waste landfill sites at the end of their life-cycle.

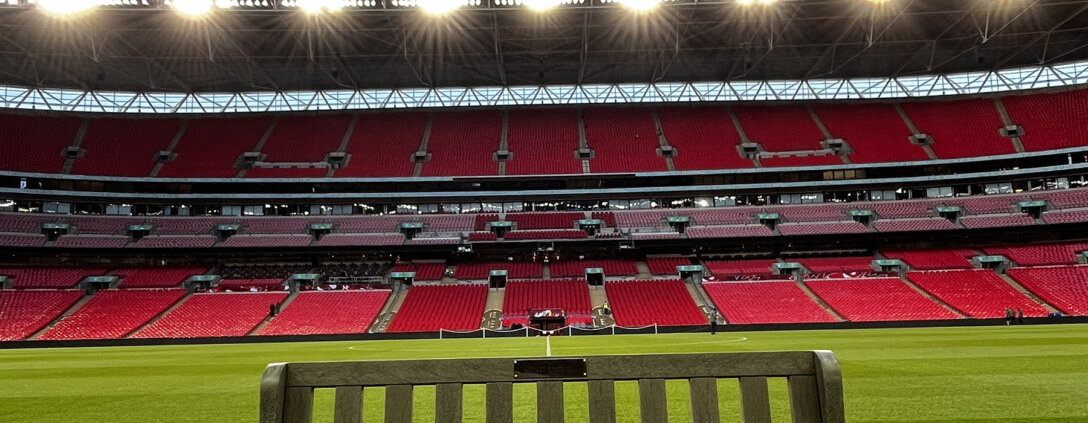

Now, the team at Wembley Stadium have come up with a process which means the plastic can be extracted from the pitch and repurposed. In the first of its kind, they have created a bench, made entirely out of plastic from a pitch that saw the likes of Harry Kane, Bukayo Saka, Lauren James and Mary Earps all perform on.

Karl Standley is the Grounds Manager at Wembley Stadium. He said: “Extracting the plastic from a hybrid pitch is notoriously difficult, due to its compound and structure. When we first mooted the idea of recycling it, we were told it couldn’t be done. However, we were determined to find a sustainable answer to the problem.

“It’s been a long journey, testing and re-testing, but we have finally come up with a solution we are happy with.

“Creating something from a pitch that has had world class players perform on it is the ultimate memento. I am excited about what else we can possibly create in the future.”

Since the new stadium opened in 2007, Wembley has been committed to developing sustainable initiatives to ensure it is one of the greenest stadia in the world.

The team already recycled large elements of the pitch (rootzone and sand) back into grassroots pitches and wanted to take a lead in the research and development of a 100% sustainable process for the type of hybrid pitches installed at Wembley Stadium.

They worked with recycling specialists Circular 11 to find a suitable solution. Connor Winter from Circular 11 said: “The full circle pitch has been one of the most technically demanding and exciting projects that we’ve worked on to date, and we’re really proud to be a part of this pioneering project.

“It demonstrates that there are huge opportunities to increase plastic recycling when companies have unrelentingly high standards about what happens to the materials they use, as Wembley does, and shows the potential for composite technology to transform previously unrecyclable plastic into a resource.”

Wembley Stadium now hopes the process will pave the way for other stadiums across the UK and Europe to become more sustainable.

Karl added: “As more stadiums become multi-purpose venues, hosting a variety of sports, music and entertainment shows, there is a need to use more hybrid carpet surfaces throughout the year.

“By ensuring old pitches don’t go to landfill we can create a cycle that will ultimately reduce our impact on the environment and benefit community clubs up and down the country for a long time to come.”

The stadium team estimate that around 50 benches could be created from one pitch with scope to develop the recycled plastic into other uses within grassroots football.

The prototype bench will be placed within the stadium footprint in memory of a stadium employee who passed away last year.

For the latest industry news visit turfmatters.co.uk/news

Get all of the big headlines, pictures, opinions and videos on stories that matter to you.

Follow us on Twitter and Instagram for fun, fresh and engaging content.

You can also find us on Facebook for more of your must-see news, features, videos and pictures from Turf Matters.