A charter for excellence: James Pope took on his dream job in the middle of a pandemic but, as he explained to Scott MacCallum, after a difficult start he now truly appreciates the wonders of Charterhouse School.

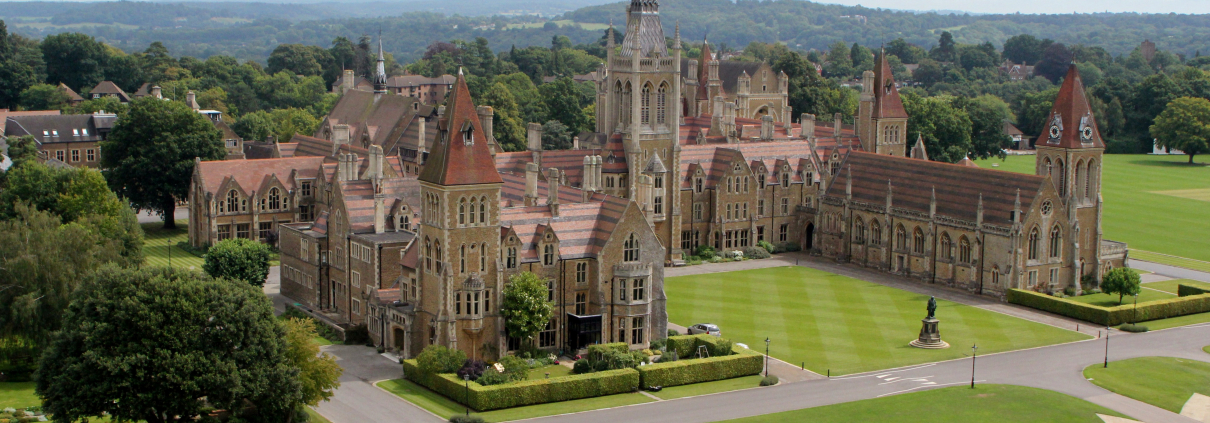

James Pope is looking out over the stunning, immaculately maintained, sports grounds of Charterhouse School and thinking back to 2020 and a year when he was pushed to his very limits.

A charter for excellence

He might smile at how he managed to move on from a workable doggie paddle to a more than serviceable butterfly in what was the essence of a sink or swim situation. To stretch the swimming analogy, he might now see it as a springboard to what he and his team is achieving going forward.

James applied for his dream job early last year. Interviews were held during early stages of Covid complete with the embarrassed, almost jokey, non-hand shaking protocols, but by the time he rolled into the spectacular grounds, for his first day in the job on May 26, we were in the depths of the first lockdown.

“The opportunity to take the job at Charterhouse was far too immense to turn down. The grounds are unbelievable, just like a film set, and there was a blueprint there which meant that it could be the best site you’ve ever walked on. It’s got that sort of capability,” said James, who had previously been Head of Grounds at St Paul’s School, in central London.

Perhaps one of the films he might have been thinking about was Mission Impossible because there is a fair chance that was the theme going around his head that first day.

“Maybe I naively took on the job thinking that it would all have blown over by July or August. We’d be out of the woods by September, and that everything would be fine by the new academic year. But it wasn’t to be, was it?”

James did have a full day’s handover with his predecessor, Lee Marshallsay (now at Eton), but had it been a month the chances are elements would still have not sunk in. However, Covid put pay to the opportunity of a longer handover process.

“I arrived at 7am and we had 11 hours together and Lee, who I knew from our time at Harrow together, said we should walk the site. Half an hour later we hadn’t completed the tour. All the time Lee was passing on so much information and knowledge then, at the end, he handed me a ring binder, so full it couldn’t be closed. But even then, that didn’t cover everything.”

Five weeks later having digested as much of the handover document as he could, he started.

Eleven months on, and looking back, James can’t help but wince, as, with lockdown, it meant he arrived with half of his team on furlough, including his Admin Assistant.

“I didn’t know any of the staff and I really didn’t know where anything was kept.” recalled James.

Fortunately his Deputy, Liam McKendry, had not been furloughed and, at the same time as getting to know each other, he was able to pass on what he knew.

“Liam was an absolute rock because he knew the site, although he hadn’t been here two years himself, and he knew the team and the types of situation we would be likely to expect. Without him in those first few weeks I’d have been lost as it’s a huge site full of complexities.

“However, Liam had only been on staff for a couple of years himself so there was quite a bit he didn’t’ know either. So, in many ways, we have been learning much of the site together,” said James.

“I spend the first three or four weeks trying not to be overawed, getting to know everyone and building up trust between myself and the team.”

A charter for excellence

Having arrived from St Paul’s, to a site that was five times bigger with a large forestry area to maintain, as well as a nine hole golf course and all the sports pitches it was a genuine task – made worse by the fact that James’ first few months coincided with a hot dry spell.

“It was verging on 30 degrees and our site is near enough 100% sand so it looked like a dust bowl for two months., There was nothing we could do unless it poured with rain, which wasn’t looking likely,” recalled James.

“I was concerned. I’d only just started and it’s a dust bowl. People were going to think that I couldn’t do the job. I really wanted to get stuck in, but what could I do. I’m giving myself a headache just thinking back,” said James, who added into the mix the fact that the Director of Sport was also newly appointed and, like James, learning a new job in the middle of a pandemic.

With the weather not doing him any favours and James genuinely concerned about having everything ready for September he got his first break.

“We took a bit of a gamble and started to do everything we needed to do, as if the weather was favourable, and hope that the weather would change for us. And lo and behold, it did! Someone was looking down on me. In August it rained.”

Since that early trauma, James has gone on to appreciate fully the wonderful environment in which he is now working.

“St Paul’s wasn’t a small school by any means but in terms of status and stature boarding schools like Charterhouse are the crown jewels. Ourselves, Harrow and Eton are all on the same page. Charterhouse is huge.”

It may have only been a year, but James has already seen at first hand what marks Charterhouse out as special.

“What really impresses me about Charterhouse is that when they do something they do it properly. It is not done with any element of compromise, no stone is left unturned. Every detail is covered and they want it to be the best it can be. They don’t want mediocrity and that spurs me on to produce the best as well.”

James is interesting on the subject of the day-to-day differences between his current job and his previous one.

“At St Paul’s where there is over 1,000 pupils but only 30 boarders, while there are 800 pupils at Charterhouse. At St Paul’s, from the moment you got there at 6.45am for a 7am start there were children already coming in and it was getting busy. Sport started at 9am and would go on to after 6, and there was sport being played six days a week.

“At Charterhouse there is breakfast, then classes before any sport and then it is only played on Tuesday, Wednesday and Saturday.

It doesn’t feel so busy, but it is much more geared up to producing quality surfaces because there is time available to work on them. The window of opportunity to get things done is much bigger. That said there are many more surfaces to produce.”

The school has a strong reputation for having sports surfaces which rival the very best.

“That goes back to when Dave Roberts was here, and look what he’s gone on to do (Head of Grounds at Liverpool FC). He made a huge mark here and guys on the team still talk about him now. A really nice bloke who brought that professional football and sport ethos into the school environment.”

While not treating his first year as a false start, priorities were certainly different than they would have been had Covid not struck, and James is certainly looking forward to tackling his new job under more conventional circumstances.

“I’d like to think in six months’ time we’ll be in a position to say this is the start. We’ll have come through a period of not knowing; of toing and froing, of preparing for sport, of not preparing for sport; should we spend money on that or not as we don’t know what is going to be happening.

“Going forward the Director of Sport will know how he wants to work and mould his department and that will have a direct impact upon us as a team.”

And from his own perspective James will be looking at what products work on the Charterhouse site.

“The great thing here is that the size of the site lends itself to trialling products which makes us far more competitive when it comes to negotiating prices. Because we have so many pitches we can dial down on what is going to work for us.

A charter for excellence

“We will be constantly trialling to see what works, and even if it does work, we will then ask if we still do better. We don’t want to be short changed. It also makes us popular with the trade as it shows that we are open minded.”

His current core group of companies are ICL; Turf Care, Limagrain and AGS while machinery wise Baroness cylinder mowers are used for the outfield cutting and Dennis as well.

“I used them at St Paul’s and I’m used to it, know that it doesn’t break and that it has good back-up.”

Another huge plus for James at Charterhouse is his 14-strong team plus himself. “I think the world of them all. If it wasn’t for them, in the middle of Covid I don’t know where I would have been. They have all worked here a long time and know what they are doing and at the beginning I told them that they don’t need me to tell them what to do but just to go out do their job and that I wouldn’t be chasing them around.

“I think it gave them a new lease of life from knowing that I trust them.” So, given the difficulties of the last year what are James’ ambitions for three years down the line?

“If the team are coming into work and seeing the difference and that we are better than we were when I turned up that would make me happy. It is as much their site as it is mine, I’m just the custodian, but I’d like them to be taking pride in what they have achieved.”

After coming through a period as challenging as 2020 and the first half of 2021, and that springboard boost, no-one would bet against it.